Industrial trends for 2024. What should a factory invest in?

Technological progress is advancing, and with it, new challenges that factories must face are inevitable. Maintaining competitiveness in the industrial environment requires not only reacting to changes and monitoring current industrial manufacturing trends but also actively shaping the future of production. The new year is a time to evaluate the adopted strategies in previous years and set new directions for action. This time encourages us to reflect on improving current manufacturing processes and creating new standards for the operation of production facilities.

Hence, the question arises: What industrial manufacturing solutions should a factory invest in for 2024? The answer is certainly found in technological innovations that will not only shape the industry in 2024, but may also become key elements of manufacturing industry strategy in the coming years.

Top trends of industrial technologies that will revolutionize the functioning of the 2024 manufacturing industry.

1. Advanced analytics in Smart Factories. The use of Artificial Intelligence models and machine learning in the industrial world.

The Digital Factory, also known as Smart Factory, is the concept of the future factory based on data. It's not just a modern concept but a factory idea that leverages advanced digital technologies such as IoT sensors (Internet of Things), advanced telecommunications protocols, and artificial intelligence to enhance and optimize manufacturing operations. The Smart Factory aims to create an intelligent and flexible production environment through technology integration.

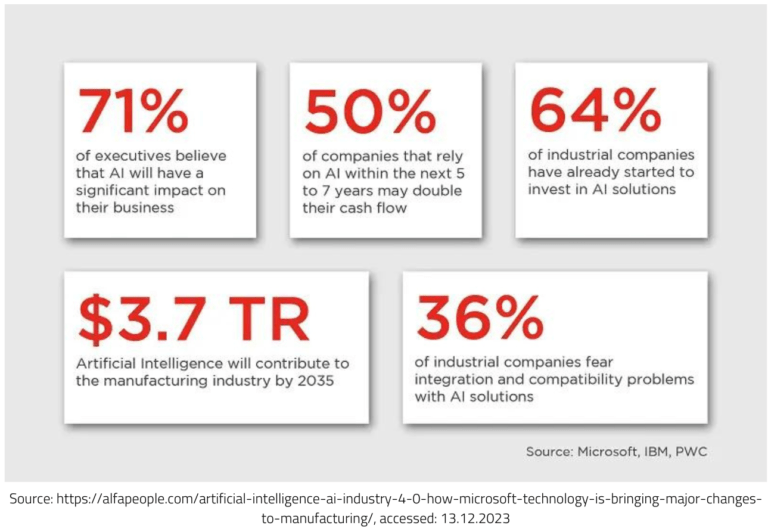

The digitization of production, including large amounts of data gathered in industrial manufacturing systems such as SCADA (Supervisory Control and Data Acquisition), MES (Manufacturing Execution System), or ERP (Enterprise Resource Planning), enables data analytics and drawing relevant conclusions. Factories can use artificial intelligence to improve both manufacturing business models and technological processes. According to Gartner's forecasts in the report “Top 10 Strategic Technology Trends for 2024," by 2028, 75% of software engineers employed in enterprises will work with AI coding assistants. As of early 2023, this percentage was below 10%. Current data also shows that AI-utilizing hardware is already present in 64% of manufacturing companies worldwide.

Machine learning in manufacturing

Creating machine learning models begins with teaching artificial intelligence about our processes based on historical data. Subsequently, trained AI systems can attempt to predict processes in real time within the plant. The more training data we gather and provide, the better we educate the AI model. This approach allows us to anticipate potential anomalies and undesired situations on the production line and react in advance — before the problem arises.

In summary, data becomes a source of knowledge, and continuously developing and refining AI automation is the key to creating intelligent production systems. The benefits of its application in smart manufacturing idea include:

- Forecasting, and preventing anomalies

- Data-driven maintenance

- Real-time response to undesired situations

- More efficient detection of areas for process improvement

- Optimization of production process efficiency

- Improve manufacturing efficiency

- Greater flexibility in dealing with variable production conditions

- Making more accurate production decisions

- Cost savings

To learn more about the importance of data in the manufacturing industry, check out the article: “Data monitoring in intralogistics – Logistics 4.0”

2. Collaborative and industrial robots that enhance production efficiency

Production automation has reached a new level with industrial robots and collaborative robots (also called cobots). Both perform tasks that require high precision, force, or repeatability. This allows employees to be delegated to more creative tasks. Industrial robots are programmable, easy to operate, and can be used in various production and warehouse processes, such as packaging or sorting. New production lines incorporating robots will help us increase production efficiency, ensure manufacturing workers' safety, and maintain high-quality final products. Learn more about robots in manufacturing plants in our blog article “Industrial Robots in Production Automation”.

The above image is an example of a mobile production station that was built through the integration of the autonomous mobile platform FORMICA 1 by AFORMIC with a collaborative robot. This combination enabled the self-driving platform to perform production tasks on its deck. Learn more about this solution here.

3. Technological trends in transportation systems

Intelligent transport systems have become a key element in efficiently moving materials within a factory. Among them are AMRs (Autonomous Mobile Robots) and AGVs (Automated Guided Vehicles). Both AGVs and AMRs are used to move materials and products around the production hall, as well as to automate internal transport and picking processes. They differ in their methods of navigating through the factory, load capacity, and responsiveness to changes. You can read more about the differences between them in the article: “AMR or AGV? The Key to Factory Success.”

Autonomous mobile robots enhance employee safety in the factory by automating dangerous and repetitive tasks (e.g., manual material handling) and activities in hazardous areas. Moreover, they can work continuously, eliminating downtime and minimizing the risk of human errors. Incorporating robotic transport into manufacturing processes allows for increased efficiency in logistics operations, automates material flow processes, and shortens order fulfillment times. Below, we present AIUT's AMR.

Our intralogistics platform with Formica AMR mobile robots has received the main award in the prestigious Innovative Product for Logistics, Transportation, and Production 2023 competition, organized for nearly 20 years by the Eurologistics Media Group. The jury acknowledged our advanced technology, confirming that it is an innovative solution for the logistics and production industries. Undoubtedly, this innovation will bring numerous benefits and shape the industry in the coming decades. We invite those interested in implementing autonomous mobile robot technology to contact us.

4. Automated storage and retrieval systems (ASRS). What are the main drivers for using them in your facility?

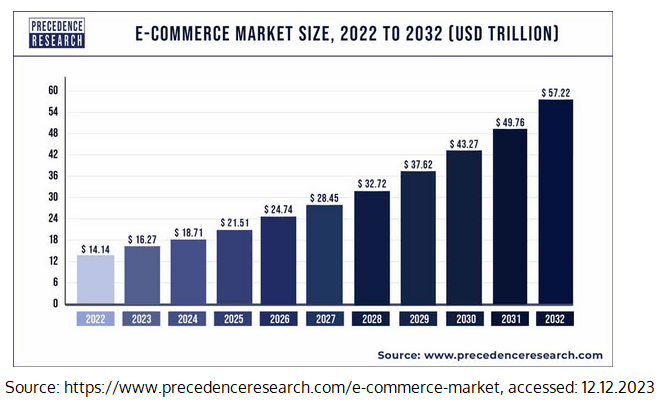

According to the Central Statistical Office, there has been an increase in the share of online sales in total sales in Poland by 0.6 percentage points — from 7.7% in June 2023 to 8.3% in September of the same year. This trend is consistently growing, and e-commerce continues to evolve. Precedence Research forecasts indicate that the global e-commerce market size will reach approximately USD 57.22 trillion by 2032, up from USD 14.14 trillion in 2022, growing at a CAGR of 15%.

So, how to prepare a warehouse or distribution center for the upcoming growth in e-commerce?

We recommend seeking solutions in ASRS — Automated Storage and Retrieval Systems. Among them, notable options include high-bay warehouses, transport systems, and automated production buffers.

High-bay storage systems allow for maximizing the use of warehouse space by increasing storage density per unit area. Instead of investing in the costly construction of a new traditional warehouse, it's worth considering the automation of storage processes, leveraging the potential of high-bay storage racks. To learn more, check out the blog article “Automated Warehouse vs. Traditional: What are the benefits of such a transformation?”

On the other hand, transport systems ensure safe and efficient product transport from one point to another. Conveyor systems, including belt, roller, chain, or modular systems, are among the distinguished transport arrangements. More information, you can read the blog article “Conveyor Systems: The Key to Efficient Internal Transport”

5. Development of 5G technology in industry – IoT sensors

As mentioned earlier, reliable data is crucial for analysis and the use of artificial intelligence models. With the development of 5G technology, which offers faster data transfer speeds, lower latency, and greater network capacity, factories will gain quicker and more reliable access to information. The use of 5G technology will enable better coordination of processes, remote device monitoring, and the implementation of advanced IoT (Internet of Things) solutions on a large scale. Statista predicts that by 2028, the number of 5G subscriptions worldwide will drastically increase to over 4.5 billion. For comparison, this number was 0.12 billion in 2019.

Industrial IoT (ang. Industrial Internet of Things — IIot)

The use of 5G technology enables the support of a vast number of devices connected to the network. Implementing a network of interconnected IoT devices in a factory or warehouse is essential for collecting and transmitting information from the real world to the digital realm. IoT sensors are devices that gather environmental data and then transmit it over the internet to relevant systems. Moreover, they contribute to creating a sustainable urban environment by integrating them into city infrastructure. This allows cities to become more connected, efficient, and tailored to the needs of their residents. Smart meters allow us to monitor and optimize, for example, energy or water consumption, which can reduce costs associated with energy management and minimize its impact on the environment. Discover the applications of AIUT's IoT sensors.

6. Next generation of factories — sustainable development and production, achieving carbon neutrality

Issues of sustainable development are currently a priority in many industries. Factories incorporate new strategies involving investments in more environmentally friendly technologies and production processes. The adopted strategy will contribute to environmental protection, gain customer favor, and compliance with future manufacturing industry regulations. One of them is the industrial manufacturing policy, called the European Union's Green Deal. Its goal is to guide the EU towards an ecological transformation, with a significant focus on sustainable production, and ultimately, achieving climate neutrality by 2050.

Summary

Implementing modern technologies in the field of automation, robotics, and intralogistics is not only an investment in the present but also a key to the future success of your factory. Adapting to changing market conditions and implementing global industrial trends is the recipe for increasing production efficiency and maintaining competitiveness in the market.

If you are interested in introducing industrial manufacturing innovation, feel free to reach out to us.

As an integrator of industrial automation and robotics solutions, we assist in selecting innovative solutions aligned with the latest industrial trends and tailored to the needs of your manufacturing facility.