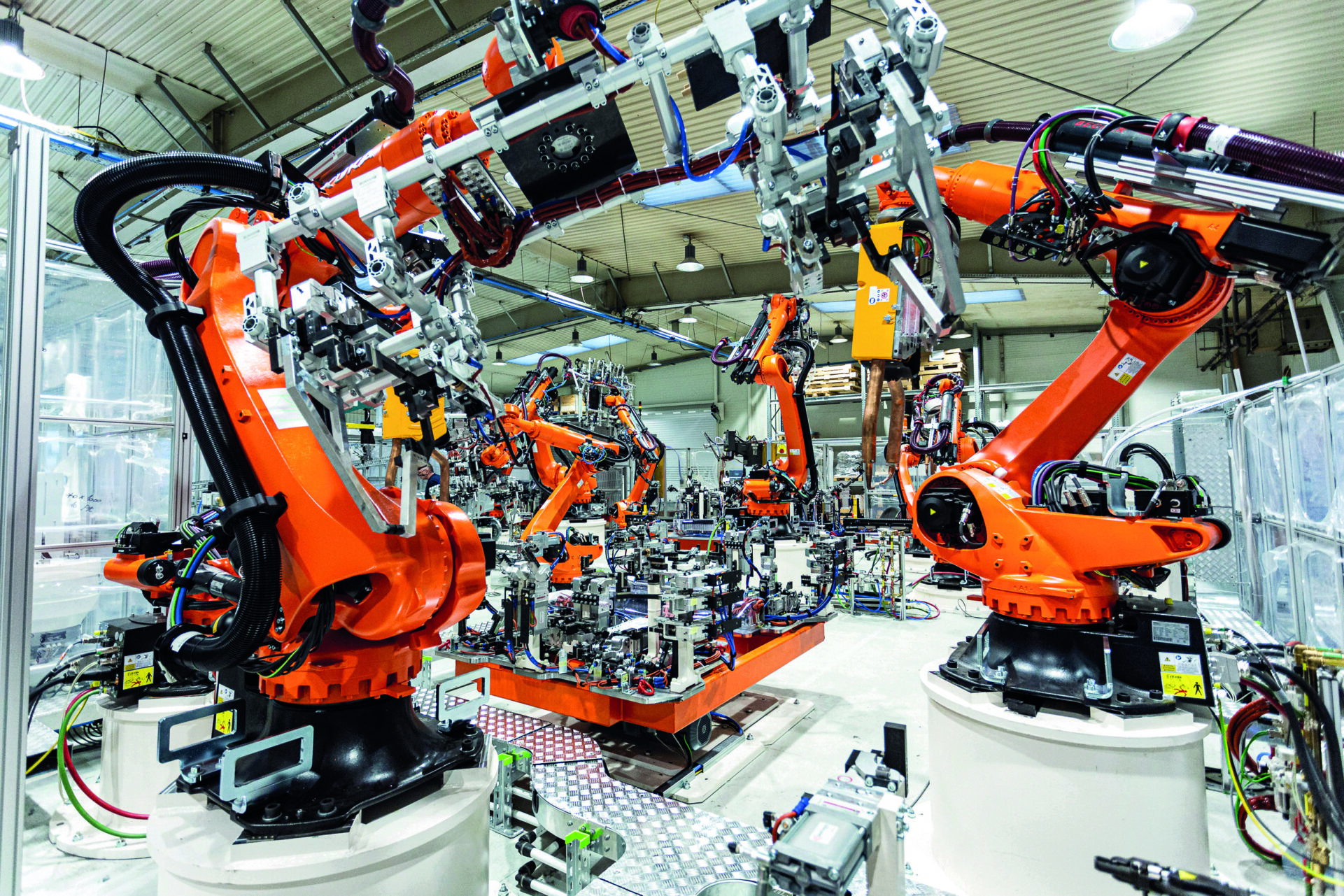

Welcome to the world of smart manufacturing

The future of the industry is digital. Manufacturing companies face challenges that demand a complete redefinition of existing process management strategies and the introduction of new products to the market. Gain an edge by building a digital ecosystem for your factory with us.

Data-driven manufacturing: time to change the rules

Unlock the potential of data with the right solutions. AIUT brings together over 30 years of experience in industrial automation and robotics, backed by the unique expertise of our 700-plus engineering team, to turn your digital transformation dreams into reality. We design and implement comprehensive IT ecosystems that open up new opportunities for optimization and expansion in your business. Welcome to the era of Industry X.0.

Comprehensive system integration: from Factory 4.0 to Factory X.0

The key of Industry X is an integrated IT ecosystem that facilitates seamless information flow across the entire chain - from design to production and logistics.

As leaders in deploying Industry 4.0 and Industry X.0 solutions, we provide a comprehensive suite of services to modernize factories —from process design and machine construction to the comprehensive integration of advanced control systems and the development of digital industrial ecosystems. Our projects enable:

- Full integration of IT and OT systems,

- Enhanced efficiency in manufacturing and logistics processes,

- Automated factory management through digital transformation.

A single digital ecosystem for managing your facility in real-time.

Boost autonomy and cut down on risks. The full digital transformation starts with automation and robotics in manufacturing, where we begin to integrate data from various sources into one unified management platform. Our solutions bridge the physical and digital worlds, providing transparency, enabling predictive maintenance, and enhancing resource management. This approach sets new standards in enterprise management, addressing many challenges associated with operating dynamic and complex industrial environments.

Instead of multiple applications, use a single integrated ecosystem for data exchange and analysis. At AIUT, we design solutions that enable free information flow from various sources, ensuring efficient production and business processes.

How to integrate data from various sources?

Using modern technologies such as cloud services, the Internet of Things (IoT), artificial intelligence (AI), 5G networks, robotics, and digital twins, we're transforming the way businesses operate: increasing efficiency, reducing costs, and improving the quality of management and services provided by companies. But it's the deep integration of these technologies into processes that builds resilient and adaptable industrial environments. With our solutions, your manufacturing and intralogistics processes will quickly adapt to sudden changes and new challenges.

Traditional systems like ERP, MES, and SCADA are essential for managing production. However, with the shift from mass to customized batch production, the need to integrate these systems with Operational Technology (OT) grows. This integration gives you a detailed view of factory operations, enabling dynamic management and real-time optimization.

Benefits from integrating IT and OT include:

- Centralized data and comprehensive analysis.

- Holistic management of all factory processes, from production to logistics.

- The ability to create larger ecosystems that include ERP, MES, EAM/CMMS, and WMS/WES.

AIUT's expertise in building IT Ecosystems

- Audit and analysis of the current business situation.

- Development of a new management strategy with digital tools.

- Creating detailed design and implementation documentation.

- Designing a comprehensive IT ecosystem tailored to the company's needs.

- Cybersecurity: secure system architecture.

- Preparing the environment, implementing, and integrating advanced IT solutions tailored to specific areas of the company's operations.

- Global technical and operational support.

- Ongoing monitoring and development of the ecosystem to meet changing business needs.

Industry X.0 – the answer to today’s new production challenges

Industry X.0 is redefining how companies operate and manage projects. Central to this approach is the integration of cutting-edge digital technologies with manufacturing and logistics processes. This concept encompasses a wide range of innovative solutions and practices designed to enhance efficiency and agility across industrial operations.

Why invest in digital industrial transformation? Unlock new opportunities and benefits

- Autonomous management of production tasks and management processes.

- Reduced downtime thanks to predictive analytics and real-time monitoring.

- Real-time production & internal transport management.

- Better resource utilization & full product traceability: system integration enhances machine and workforce efficiency while ensuring process and product monitoring.

- Data-driven decision making – advanced analytics empower managers to make smarter choices.

- Competitive advantage: a digital ecosystem enables faster responses to market shifts and customer demands.

- Advanced maintenance management: tools and methodologies that support preventive maintenance for industrial equipment.

Prototype, produce, and bring to market faster with the Industry X.0 model

We provide end-to-end business process execution to help you bring your products to market faster. How do we do it? While working with our clients on product or device design, we also begin developing the production line. By using real-time data from the prototyping phase, we make adjustments as necessary. This approach ensures that once validation and testing are complete, production can start almost immediately.

Digital Transformation Services: where to start?

Stay ahead. Optimize. Grow. Turn your factory into a future-ready digital ecosystem and gain full control over your processes—from production to logistics. Looking for a trusted partner in digital transformation? Get in touch with AIUT’s Digital Industrial Transformation experts through our contact form.