- Mobile production stations

- Intralogistics and production transport

- Solutions

Mobile production stations

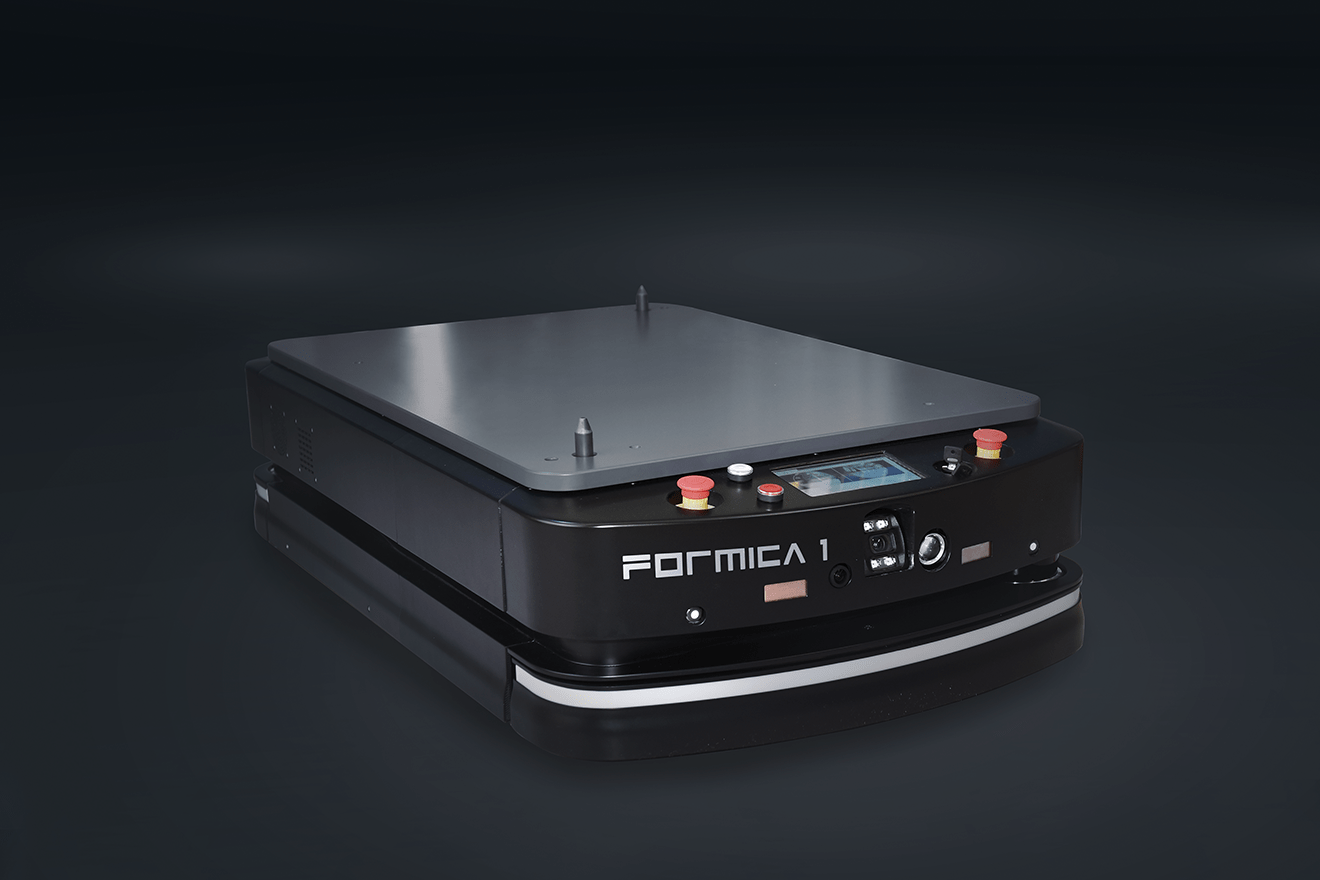

Equipped with advanced software and security systems, our intelligent FORMICA 1 AGV robots can serve as product transporters, as well as mobile production stations.

By automating and making the production and logistics processes more flexible, we have introduced a new link to the intelligent production line. Discover FORMICA 1 our autonomous, mobile transport and production platform.

A new link in the intelligent production line

Discover FORMICA 1. This autonomous, intelligent robot can support the work of enterprises with the traditional-mannered supply of components needed at production lines – acting as an independent transport platform integrated with the production line.

Mobile production stations

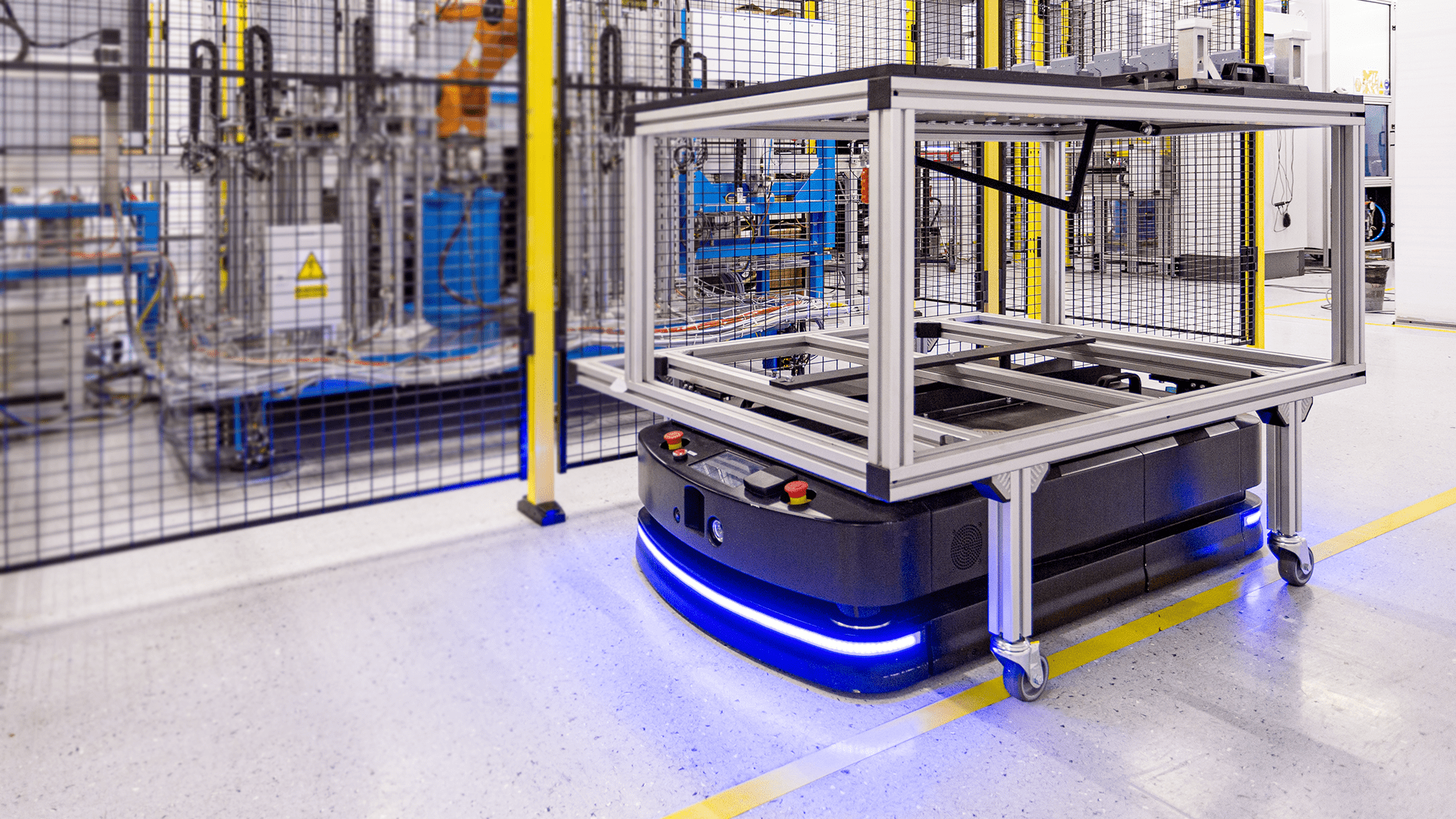

The range of FORMICA 1 robot functionality allows us to easily adapt this mobile platform to the changing needs of a particular company. Thanks to AIUT technology, the role of our vehicles can be transformed into self-propelled, cobot-equipped machinery, that's capable of performing specific tasks directly on-board. This is how AIUT mobile production stations are created - a new link in a flexible production line.

New production possibilities

Mobile production stations give enterprises new production possibilities, allowing the factory's offer to be extended without the need to interfere with the key manufacturing process. Thanks to our technologies, we can create independent mobile production lines directly on the location. These lines would be operated by FORMICA 1 platforms. Want to know the details?

FORMICA 1 capabilities and advantages

FORMICA 1 is an intelligent vehicle, ready to work in any industrial space. The solution can be fully adapted to the needs of an enterprise, integrated with existing industrial automation systems and superior production management systems. The robot has a lifting capacity of up to 1 ton (extendable). It moves smoothly in both directions and rotates relative to its midpoint.

The extensive navigation system based on LIDAR technology allows the robot to create a virtual map of the work environment and track traffic in its vicinity to choose the optimal route (without interfering with the infrastructure of the plant). The vehicle makes decisions based on both real traffic and information from the fleet management system, adapting its response to the situation (it can slow down, stop, change the route, and others). FORMICA 1 anticipates and bypasses high-traffic zones and excluded areas. The intelligent analysis allows the platform to predict various events. Performing the function of a mobile production station, FORMICA 1 can transfer from point to point following the virtually designated production line.

Built-in advanced safety systems guarantee full control of FORMICA 1 operational area. The safety system allows staff to work freely near the vehicle's activity zone. The AGV is equipped with 2 scanners, enabling a 360° panoramic scanning around the vehicle. All obstacles below the laser beam level are detected by active bumpers located at the front and rear of the robot. The obstacles above are detected thanks to 3D cameras.

FORMICA 1 is equipped with a unique BlackBox module, featuring a camera system and keeping a record of the vehicle's operating parameters. Also, an IMU module is implemented, verifying vibrations, overloads and external impacts - providing full insight into the operating history of the robot (with the ability to retrace events).

FORMICA 1 comes in two variants: with a lifting transport plate or with retractable coupling pins. In the first option, the robot verifies the transported load mass. For safety purposes during the operation, the center of the load's gravity is checked repeatedly. The power is supplied by long-life batteries (with operating times up to 8-10 hours) and an extremely fast vehicle charging time.

We provide our clients with a full warranty and post-warranty service for implemented projects, throughout the entire investment life cycle. This is a common complementary practice while working with AIUT. With the highest standard of services in mind, we provide the option of our qualified 24/7 support service. For more info, visit our Support page.

We are a mature business partner. Our solutions allow enterprises to significantly optimize processes and reduce costs, as well as improve the quality of services provided. To support these declarations, a flexible approach to achieving business benefits as part of our projects is brought.

We offer various scenarios for cooperation - from technical support and consulting in traditional models, to sharing responsibility for achieving goals (KPIs) for specified areas in the PRaaS model - Process Responsibility as a Service - which guarantees business benefits for AIUT partners.