- AiuTwin – Industrial digital twin platform for modern factories

- IT EAM

- IT for industry

- Solutions

AiuTwin – Industrial digital twin platform for modern factories

Introduction to digital twin – a new industrial standard

A digital twin is a dynamic, real-time updated model of a physical object or process – from individual machines to entire production lines. This technology enables precise reproduction, monitoring, and optimization of industrial operations. That’s exactly what AiuTwin is designed for – our integrated digital twin platform created for demanding production environments.

Comprehensive digitalization of the production plant

AiuTwin combines state-of-the-art technologies with AIUT’s 20+ years of experience in digital infrastructure and process modeling. It’s more than just a digital twin – it’s a complete environment for managing your plant, safety, logistics, and information. The platform was developed to help companies transition to the Industry X model and Dark Factory concept, where human involvement is minimized.

What does AiuTwin offer?

The Real-Time Location System (RTLS) enables tracking of workers and vehicles in the production hall. We create virtual safety zones, send alerts about hazards, and support evacuation procedures. AiuTwin can react instantly – for example, by stopping a production line when someone enters a hazardous area.

Thanks to integration with AMR fleets and traditional vehicles, AiuTwin allows you to plan and control traffic in the hall – from vehicle routes to collision analysis and access control. All to ensure smooth operations and full safety.

Before you implement changes on the floor – test them first. AiuTwin enables simulation of logistic and production layouts through integration with tools like Siemens Plant Simulation and Aformic Qursor. It’s a real support for process optimization.

Imagine your factory displayed like Google Street View – with data layers and 3D models of objects. That’s what MaxVision offers – our advanced visualization system that helps manage space and assets.

Everything in one place – in line with international standards (ISO 81346, IEC 61355, ISO 55000). AiuTwin integrates with SCADA, MES, GIS, EPLAN, and IIoT systems to create a coherent information environment.

Ready for the factory of the future

AiuTwin allows you to build a consistent, fully integrated digital twin architecture for future-ready plants – flexible, scalable, and secure. With dedicated modules, we help companies move toward higher levels of digitalization – from Factory X to fully automated production environments.

Deployment support and additional services

AiuTwin is more than just technology – it’s a team of experts ready to guide you through the transformation process:

- consulting and designing digital twin architecture,

- implementation and integration with plant systems,

- training and knowledge transfer for technical teams,

- maintenance strategies and failure prediction,

- service and post-warranty support.

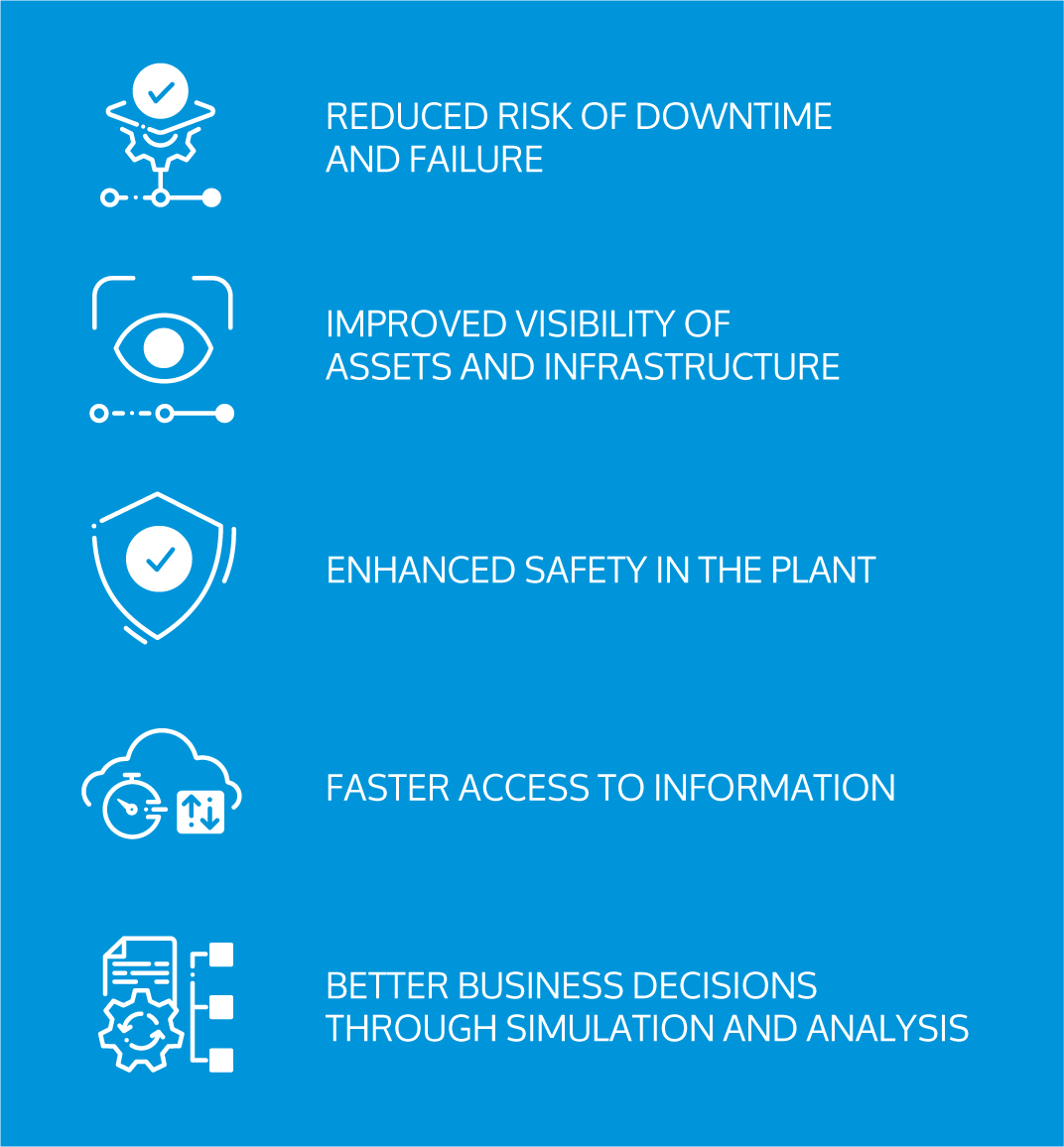

What are the benefits of AiuTwin?