How does the electrification of cars change the automotive industry?

In this article, you will find out:

-

how the automotive market is changing and how the trend of electric vehicles is shaping up in Poland and worldwide?

-

what is the electrification of cars, and how does it work?

-

what are the different types of electric vehicles (EV)?

-

will mandatory full electrification lead hybrid electric cars to replace those with internal combustion engines?

-

about the disruptive automotive trends in vehicle electrification technologies used by the industry leader.

The development of the automation industry is closely tied to the changing structure of cars, especially with the increasing automation, autonomous vehicles, and electrification. Creating more advanced automation and robotics systems requires the development of new technologies and production processes to ensure the proper functioning of modern vehicles.

In the automotive industry, there is a noticeable trend of phasing out internal combustion engine (ICE) vehicles in favor of those with electric powertrains, which are more climate-friendly and meet environmental requirements. We're talking about battery-powered cars (BEV), hybrid electric vehicles (HEV), and plug-in hybrid electric vehicles (PHEV). The transition from current vehicles to zero-emission cars is closely tied to EU regulations. This is because road transport accounts for one-fifth of CO2 global emissions, and the climate policy goals of the European Union aim to cease the production of combustion engine cars after 2035.

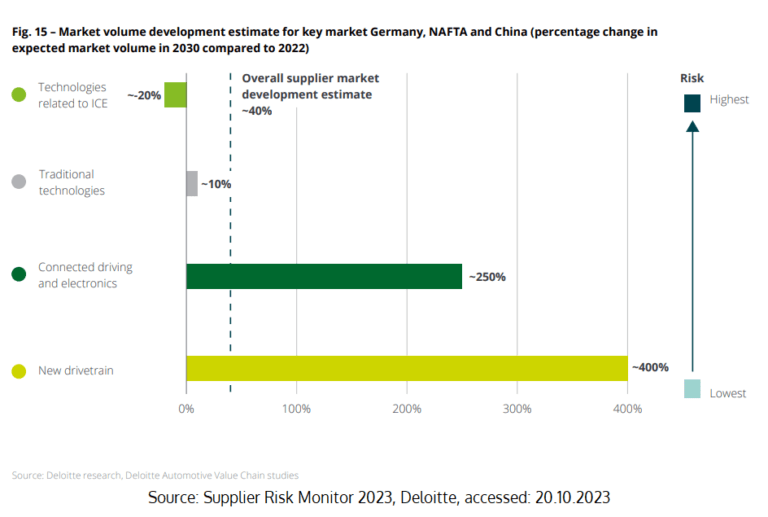

It is estimated that by 2030, the number of vehicles with alternative propulsion systems compared to those with internal combustion engines (ICE) will increase by up to 50 percent. According to the Supplier Risk Monitor 2023 report by Deloitte, forecasts indicate a general market growth of automotive suppliers in NAFTA countries (Germany, North America, and China) by approximately 40 percent by 2030.

The chart above clearly indicates that estimates regarding the size of the traditional technology market will only increase by approximately 10%. On the other hand, it is anticipated that the market related to internal combustion engines (ICE) will decrease its revenues by about 20% by 2030. This reflects the shift in focus and investment towards technologies of alternative mobility, particularly in the context of the growing prominence of electric vehicles and the decline of fossil fuel vehicles.

How do vehicle electrification trends look in Poland now?

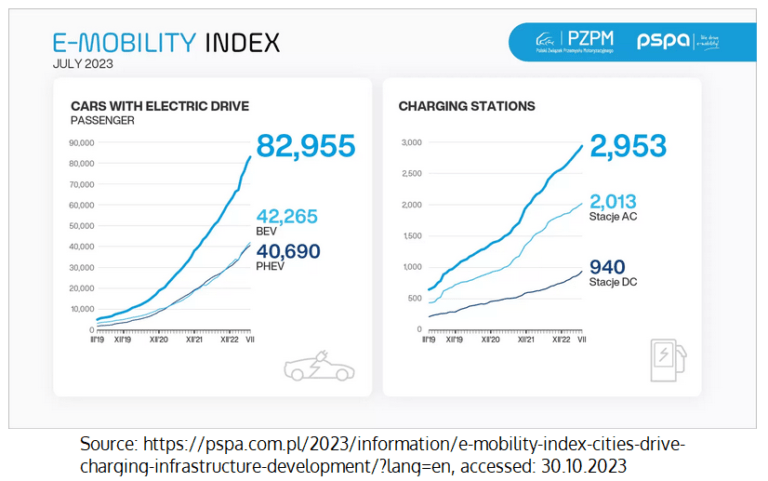

According to the Polish Alternative Fuels Association, during the first three quarters of 2023, there was an increase in the number of electric cars (BEV) by 13,293 units, which is 57.7% more than in the same period in 2022. The development of charging infrastructure on urban roads is also evident – by the end of July 2023, there were 2953 publicly accessible electric vehicles charging stations (5884 points) in Poland. Slow alternating current (AC) chargers constituted 68%, while fast direct current (DC) charging stations made up 32%.

Drive to electrification in the automotive industry. What are the chances of success for full electrification of cars?

The increasing electrification trends bring about significant changes for the automotive industry, which recently had to weather the automotive supply chain crisis with semiconductors arising due to the COVID-19 pandemic. Currently, amidst challenges such as the war in Ukraine, the industry is grappling with high production costs, energy prices, rising raw material costs, supply chain disruptions, and currency fluctuations. However, despite these obstacles, the long-term forecasts for the automotive industry are positive. Automotive is an industry of constant change, and the challenging situation it faces motivates action, and the exploration of new approaches, and serves as an opportunity for sector development. Hence, the question arises: where is the automotive industry heading, and what changes can we expect in the near future?

Electric vehicles' role. How does vehicle electrification work?

Vehicle electrification represents a fresh perspective on the automotive industry. The electrification process involves replacing traditional internal combustion engines with electric ones, aiming to reduce greenhouse gas emissions and air pollution. Currently, there are distinctions among battery-powered cars (BEV), hybrid electric vehicles (HEV), and plug-in hybrid electric vehicles (PHEV). Each of these vehicle categories contributes to the reduction of CO2 emissions.

Hybrid engines, plug-in types, or fully electric vehicles?

BEVs rely entirely on the energy stored in the battery to power the electric motor. Hybrids have both an internal combustion engine and an electric motor. They primarily draw power from the kinetic energy of the hybrid car, recovered during braking, and then converted into electrical energy. This enables them to charge while driving and consume less fuel. On the other hand, plug-in electric vehicles combine features of hybrid and fully electric vehicles. They have a larger battery that can be charged from an electrical socket, allowing for short-distance travel solely on electric power.

What are the benefits and challenges of vehicle electrification?

-

Clean energy, reduction of pollutants — decarbonize road transport

An electric fleet is a step toward a more sustainable future. Eliminating emissions — reducing CO2 — is not only environmentally beneficial, but also a response to the growing challenges associated with climate change.

-

Power efficiency and performance — lower fuel costs

Powering electric cars is cheaper compared to the fuel costs of combustion engine vehicles. Additionally, the maintenance costs of electric transportation vehicles are significantly lower, constituting 40% of the service costs of combustion engine vehicles. However, it's important to note that charging battery electric vehicles takes several hours and that the electric car distance has a shorter range.

-

Electric vehicle supply equipment – development of charging infrastructure and service points

As the electric car market increases, the development of specialized charging infrastructure becomes essential. New electric vehicle charging stations (also known as electric vehicle supply equipment - EVSE) and service points make using electric cars more convenient and accessible, enhancing the attractiveness of electromobility. However, when planning a route, it's crucial to consider that suitable infrastructure is not yet available everywhere, and the time required to charge an electric car is significantly longer than traditional refueling for combustion engine vehicles.

-

Quiet operation mode

Emission-free electric cars operate much quieter than those with combustion engines. This increases travel comfort and allows for an even more enjoyable driving experience.

What changes have been introduced in electrification areas of car production by automotive industry leader – Toyota?

The rising popularity of vehicle electrification trend is impacting traditional manufacturers of combustion engine cars. Automotive companies must adapt to new market trends by adjusting their strategies and investing in electric vehicle development.

One of the leading electric vehicle manufacturers that accelerated the electrification of cars is Toyota. As a leader in car production, Toyota aims to introduce a wide range of fourth-generation hybrid-powered vehicles globally (THS -Toyota Hybrid System) to achieve climate neutrality. This involves the modernization of technological processes and the modification or construction of new lines for the production of emission-free electric cars. Toyota's new high-quality electric vehicles are planned to be created using the modular architecture TNGA (Toyota New Global Architecture), signifying the design of automated production lines. This action will achieve higher efficiency, provide the capability to produce different types of components or drives on a single line and enhance ergonomic work conditions.

As the heart of every electric car is the battery, its size, and design impact the vehicle's performance. Toyota announces that hybrid electric cars and fully electric ones will receive a new generation of batteries by 2026. The company is also introducing the concept of a self-driving production line (already tested on selected welding lines) where components will be automatically moved between assembly stations with the help of sensors and wireless control systems.

The automotive industry leader is also leveraging 3D digital models, leading to reduced production time and increased efficiency. This approach allows potential defects to be detected during the component design stage, preventing delays associated with their re-manufacturing. Additionally, Toyota's proprietary Just In Time (JIT) concept enables the production of the right product in the right quantity within the specified time for the customer. In its research institute, Toyota utilizes artificial intelligence to train industrial robots to perform new, complex tasks to support human work in the future.

These examples are just a few of the modern technologies developed in the production process of the global automotive leader. It is evident that the development of automation, as well as the implementation of automation and robotics in production, allows for maintaining the current market position and remaining competitive. Without these solutions, creating such an advanced production process would not be possible. Therefore, we encourage you to explore our offerings tailored to the automotive industry.

As an integrator of automation and robotics solutions, we equip factories with robotic workstations and production lines, as well as technologically advanced systems, ensuring our partners in the automotive industry maintain a leading position in the market. Currently, we are implementing one of our solutions in Toyota – the Aformic Intralogistics Platform with a fleet of autonomous mobile robots Formica. See below one of the examples of our AMRs – Formica 12.

Summary

The electrification of cars is not just a change in the power source; it is a revolution that sets new standards for the automotive industry, enabling the development of industrial automation and robotics. The evolution of electric transportation vehicles requires the adaptation of factories and the entire technological process to overcome the challenges and meet the needs of the present world. Therefore, the automation of production lines plays a crucial role in the proliferation of electric cars and in shaping electromobility.

Make breakthroughs in vehicle electrification.

Learn more about our industrial automation and robotics solutions for the automotive industry.