Automated Pallet Movers: Innovations with AMR & AGV in logistics

In this article, you will learn:

-

what is the share of AGVs and AMRs in terms of their function in, respectively, revenues in the global market of AGV, and AMR?

-

what is the forecasted revenue of the market for AGV and AMR pallet movers?

-

what is automated pallet transport?

-

about the technology used in mobile robots for pallet transport.

-

what benefits does investing in a robotic pallet mover bring?

-

what autonomous mobile robots does Aformic company offer?

In today's world, the efficiency of warehouse processes is of the greatest importance, as it allows for meeting customer requirements and maintaining competitiveness in the market. Solutions such as AGV and AMR pallet movers streamline operations and increase overall warehouse efficiency. Therefore, they become integral elements of automation in modern warehouses and distribution centers.

There are many ways to classify mobile robots AGV and AMR. They can be, for example, classified based on the type of navigation technology used, the type of materials handled, depending on their shape and equipment, or according to the industry in which they are used. When looking at their division based on their function, we need to consider the goods they transport. It is not surprising that in intralogistics, the first thing that comes to mind is likely pallets — EURO PALLETS, transported by automated forklifts to various warehouse areas.

The share of AGVs and AMRs in the global market

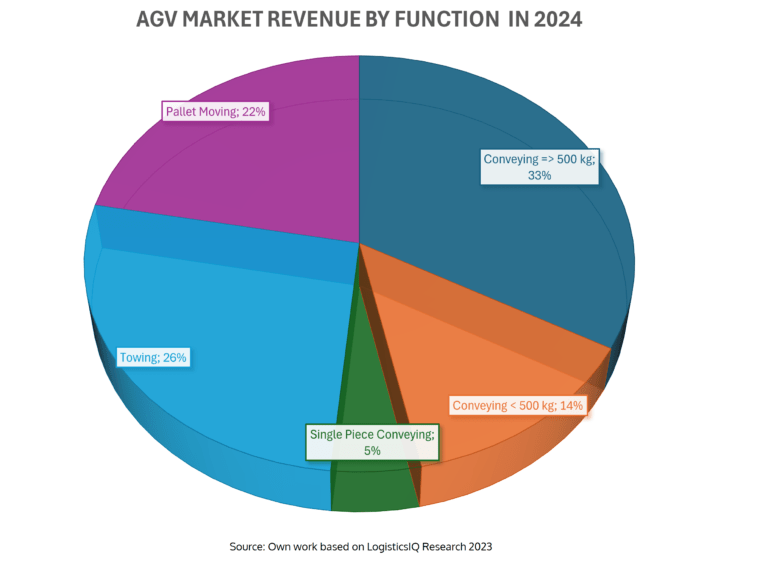

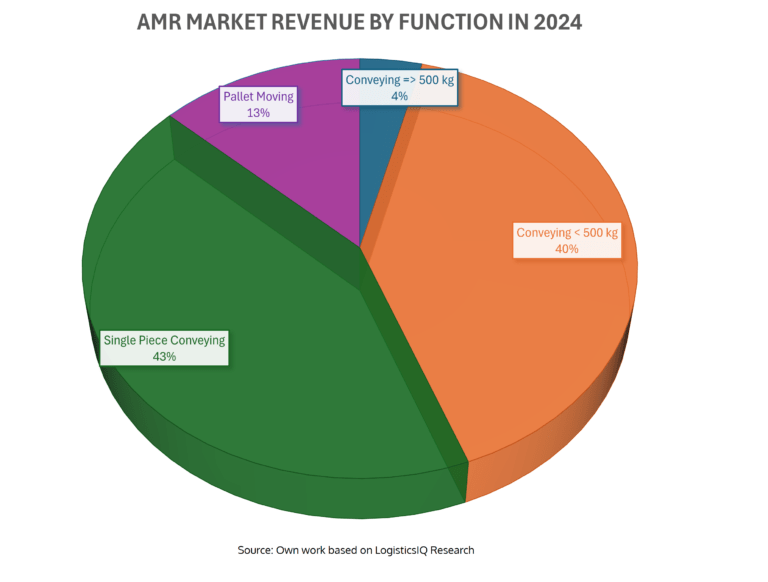

In the report by Logistics IQ Research, AGVs, and AMRs for pallet transportation (Pallet Moving) ranked third in revenues, respectively, in the global market of AGVs and AMRs (see charts below).

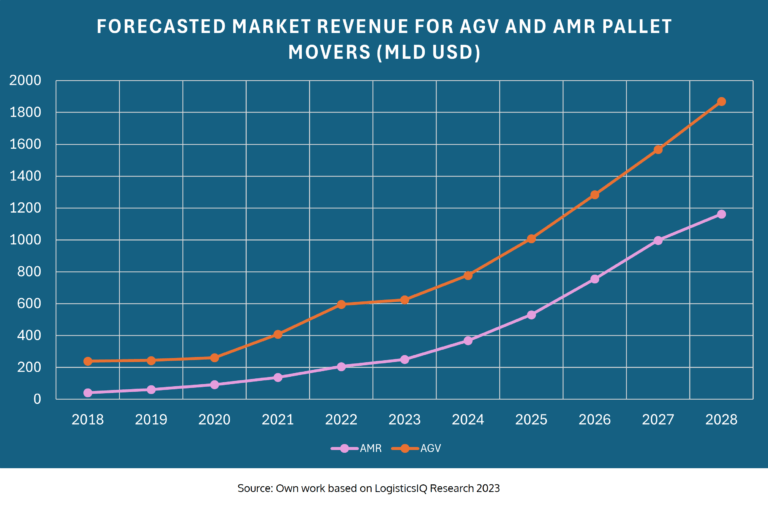

Furthermore, the revenue of the AGV market for pallet transport is increasing annually with a CAGR of 24.6%. In 2018, its value reached $240 billion, and it is predicted to rise to $1,870 billion by 2028.

As for AMR pallet movers, their revenue in the AMR market is increasing with a CAGR of 35.9%. In 2018, it amounted to $41 billion, and it is forecasted to reach $1,168 billion by 2028. The forecast period presented in the Logistics IQ Research report covers the years 2018-2028.

From the research presented in the report, it is evident that pallet moving robots are gaining popularity and increasingly replacing traditional pallet jacks, automating internal transport in warehouses and distribution centers. In this article, we will take a closer look at the tasks they perform, the technologies they utilize, and the benefits they bring to manufacturing enterprises.

Advanced pallet transport with AMR and AGV pallet movers

Automated pallet moving robots streamline repetitive operations of moving pallets between different zones within a warehouse. These robotic transport devices help meet growing challenges without human intervention in the complex world of internal logistics. Automating internal transport ensures high process efficiency, and market competitiveness, and meets the requirements of modern warehouses, factories, or other industrial facilities. Automated forklift trucks for pallet transport operate 24 hours a day, 7 days a week. This work mode significantly distinguishes them from standard solutions, which require warehouse staff involvement to execute material handling transport.

What assists automated pallet movers in navigating through the facility? — examples of utilized technology for efficient pallet transportation

Automated pallet robots are equipped with advanced technologies that facilitate movement within industrial facilities. One example of such a solution is laser scanners, typically mounted on the front or side plane of the vehicle. These advanced sensors help automated pallet robots detect obstacles during movement and navigate around them. If avoidance is not possible, they will stop at a safe distance.

To autonomously navigate, robotic pallet trucks employ various natural navigation techniques such as LiDAR (Light Detection and Ranging). This self-driving technology uses sensors that emit laser pulses to measure the distance between the robot and objects in its surroundings. Subsequently, the collected data is processed to create a map of the environment. This way, automated pallet trucks offer safe transport and movement within the facility without the need for additional infrastructure. It also allows for quick adaptation to changes in the warehouse layout or to new environments.

Automated pallet trucks also feature safety measures to maintain the required safe traveling speed. Thus, they do not pose a threat to other objects, reducing the number of collisions in the warehouse. They also have sensors at the ends of the forks, allowing precise detection of the load, and preventing damage during pickup or placement.

Automated pallet trucks are equipped with warning lights designed to signal approaching vehicles to workers. Some types of trucks also have a side load lifter, allowing them to approach the cargo transfer station and lift the pallet using high-speed roller or chain conveyors. This, unlike manual pallet trucks, eliminates the need for maneuvering, requires less space, and enables quick operation execution.

Advantages of robotic pallet movers

- Automation of repetitive pallet handling tasks.

- Increased productivity through continuous warehouse operation.

- Improved workplace safety.

- Handling of material transport without the involvement of forklift operators.

- Ability to delegate employees to perform more complex tasks.

- Cost optimization.

- Short return on investment period.

Aformic's autonomous mobile robots for automated transport of various loads

Aformic AMR solution offers highly developed AMR robots that use advanced sensors and mapping technology to adjust real-time maps of the environment and modify their paths in response to changes in the environment, such as obstacles or new paths. Our robots are implemented using process simulation to test and optimize their behavior in virtual environments. Then, during the process of environment mapping, a digital model of the environment is created.

The Qursor software allows for comprehensive management and control of all operating parameters of the system and its components.

Aformic AMRs can be designed to suit specific types of material handling equipment, like racks, pallet containers, or any containers of non-standard shapes, ensuring seamless integration and optimal performance. This flexibility allows us to provide tailored solutions to meet the unique needs of each customer. The type of supported equipment depends on the size and weight, as well as the nature of the load it is carrying.

Our system integrates multiple types of AMRs, such as underride, forklifts, or tow tractors, into a single system to manage their movement and scheduling. This can help to increase productivity, reduce downtime, and improve overall efficiency in industrial and logistical settings.

Summary

Automated pallet trucks AGVs and AMRs are revolutionizing the logistics industry, offering significant improvements in warehouse workflows and distribution processes. Their ability to autonomously transport pallets based on advanced technologies not only increases operational efficiency but also contributes to improving safety and reducing costs. Gaining popularity, these vehicles are becoming essential elements in modern supply chains.

Do you want to know more about the offer of automated pallet movers? Write to us!

As an integrator of industrial automation and warehouse robotics solutions, we have over 30 years of experience in customizing automation solutions to meet the specific needs of our clients. Become the best player in the mobile robot industry with us!