Conveyor systems: The key to efficient internal transportation

In this article, you will learn:

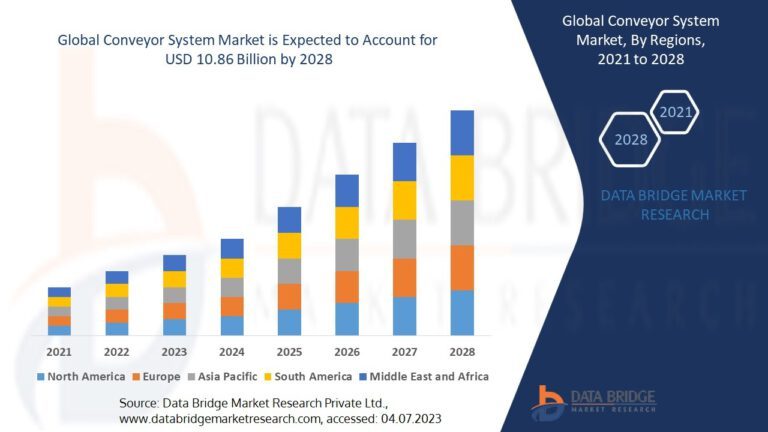

Automated conveyor systems play a key role in optimizing manufacturing processes in warehouses and distribution facilities. Their purpose is to ensure safe and efficient product transport from one location to another. According to a report published by Data Bridge Market Research, the conveyor market is expected to reach a value of approximately $10.86 billion by 2028.

The main factors listed in the report contributing to the aforementioned trend are:

- the growth in vehicle production,

- the continuous transportation of a significant number of products in the mining industry,

- the increasing volume of orders in e-commerce,

- the high demand for processed food and beverages in the food industry,

- and enhanced passenger handling capabilities at airports accelerate the growth of the global industrial conveyor market.

Research shows that companies using conveyor solutions benefit from the smooth flow of materials, space optimization, and productivity improvement. What is more, conveyor solutions also reduce the risk of accidental damage to goods and improve safety. So, what conveyor types are mostly available at conveyor system manufacturers?

What are conveyor types for material handling?

Warehouse transport conveyor systems are flexible, efficient, and ergonomic solutions for moving goods. There are various types of conveyors available on the market, including roller conveyor systems, belt conveyor systems, chain conveyors, modular conveyors, and more. The wide range of conveyor equipment allows for designing turnkey transportation systems and customizing them to fit a company's logistics system.

Belt Conveyor systems

These conveyor transport systems consist of a belt surface that moves along rollers or drums. The type of belt, its properties and dimensions, are selected based on the products to be transported on it. Belt conveyor systems can operate both horizontally and on inclines, where there is a difference in elevation (inclined belt conveyor). These types of material handling conveyors are mostly used for transporting containers and cartons. Belt conveyor systems can be used as individual devices or form a complete internal transportation line. Depending on the process, it is possible to design conveyor lines of non-standard lengths or shapes – it doesn't always have to be a straight transport line.

Roller conveyor systems

These transport systems consist of drive rollers mounted on a rotated frame, allowing for the smooth transportation of various items. The size and thickness of the drive rollers are adapted to the planned load and the type of transported unit. Roller conveyor systems, are precision devices for transporting items such as cartons, packages, crates, or bags in warehouses and distribution centers. Modules of these conveyors can be mechanically powered (powered conveyor) or operate through gravity (gravity roller conveyors).

Chain conveyor systems

Chain conveyors are durable and suitable for transporting heavy or bulky items. In this type of material handling system, objects, as the name suggests, are carried on chains. This chain-driven roller conveyor system is mostly used for the transportation of pallets in various market-standard sizes. Pallet handling conveyors can also be used in cases where pallets need to be transported transversely to the direction of transportation (often due to limited space). This conveyor technology is used for transporting goods within a single facility, such as a manufacturing hall.

Modular conveyor systems

These are proven transport systems that use modular belts. Modular conveyor systems have found applications in the food industry for moving goods both in packaging or without them (in “loose form”), for example, fresh fruits, vegetables, or baked goods. These transport systems are adapted to work in diverse conditions, including higher temperatures, humidity, or contact with diluted acids and bases.

Benefits of conveyor systems

Implementing a complete conveyor system increases the efficiency of warehouse processes and enhances internal transportation effectiveness. Additionally, it allows for optimizing space in the warehouse and streamlining the flow of various products. By supporting internal transportation, warehouse conveyors eliminate the need for manual handling of goods, minimize the risk of damage, and provide reliable operations. Therefore, they also provide high service quality. The use of conveyor technology in manufacturing processes improves safety in the factory by reducing the number of accidents related to the manual handling of heavy and hazardous items. Additionally, these solutions increase throughput, relieve bottlenecks, and maximize the productivity of material handling operations. Integrating them with the company's logistics system enables order fulfillment time reduction and increases flexibility in meeting changing customer needs.

See some photos from the installation of roller conveyor systems at one of our customers – a leader in the household appliances/RTV industry.

Summary

Automated conveyor systems have become widespread in industrial applications and represent an innovative solution for goods transportation. Belt conveyor systems, chain conveyors systems, roller conveyor systems, and modular conveyors are designed according to individual customer needs. These devices enable the efficient, precise, and safe transport of various materials. The wide variety of automated systems and availability of different types of conveyors allow for customizing the material flow system to individual requirements. The transport systems offered by conveyor manufacturers enable the implementation of warehouse automation, which in turn increases production efficiency.

If you are considering the implementation of industrial conveyors, talk to our experts about your conveyor needs.

As an integrator of industrial automation and intralogistics solutions, we assist in selecting the appropriate solutions from a conveyor equipment manufacturer. Additionally, we install custom conveyor solutions to the needs of your manufacturing facilities.