- Production lines and stations

- Automation and robotics

- Solutions

Production lines and stations

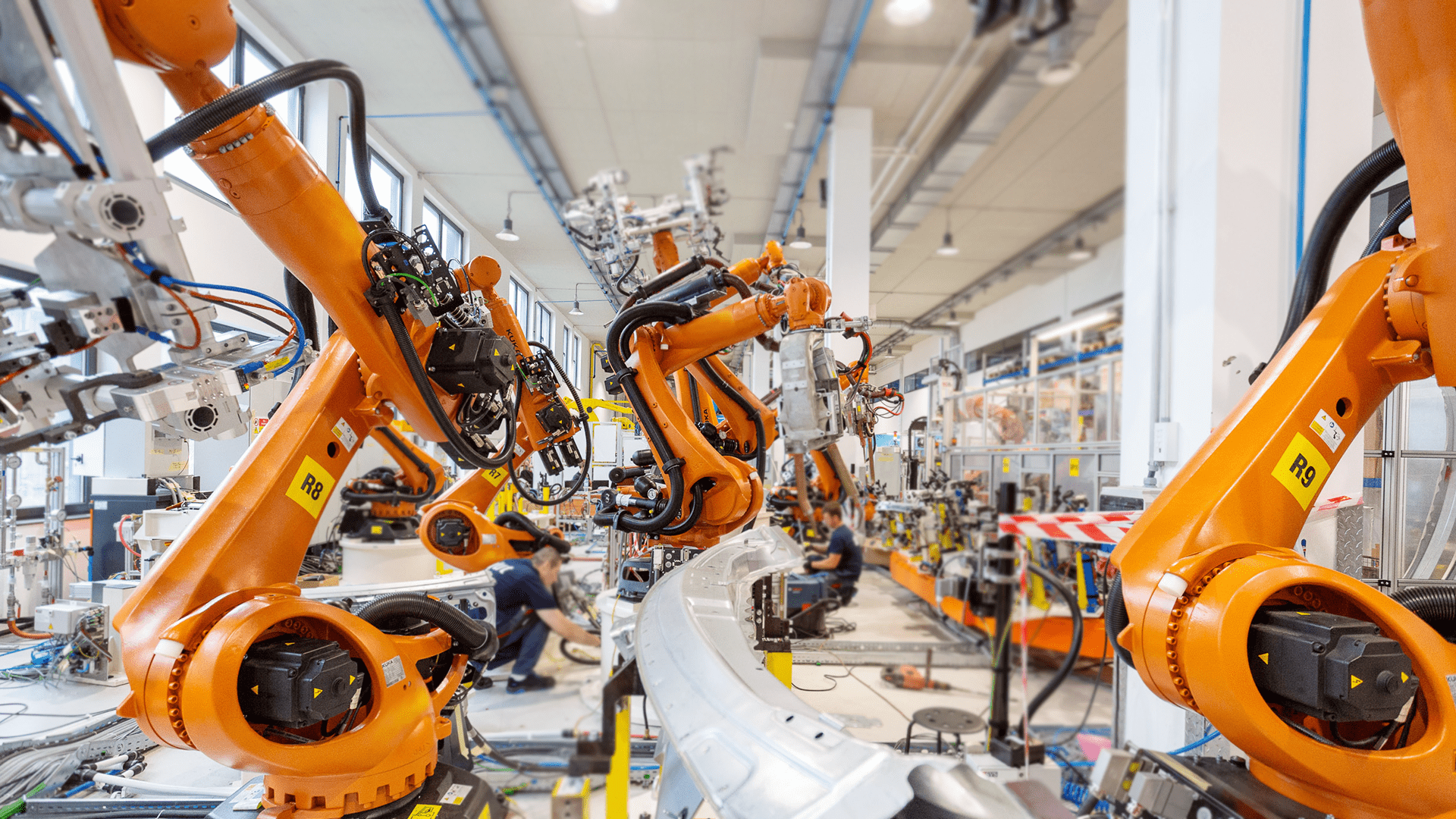

We provide our clients with automated, robotic production lines and stations. We are capable of delivering entire factories as well. We perform a complete implementation of a project, including the assembly, start-up and servicing tasks.

Robotics and mechatronics

We provide high standard turn-key services for the construction of robotic stations and production lines as well as production management systems.

We provide support at every stage of the investment process - from design to delivery and commissioning of a robotic line and production stations at the customer's site. We provide service throughout the entire product life cycle: from the initial implementation period to many years of operation.

qualified engineers

500+completed projects

3000+countries with business partners

70Individual approach and new technologies

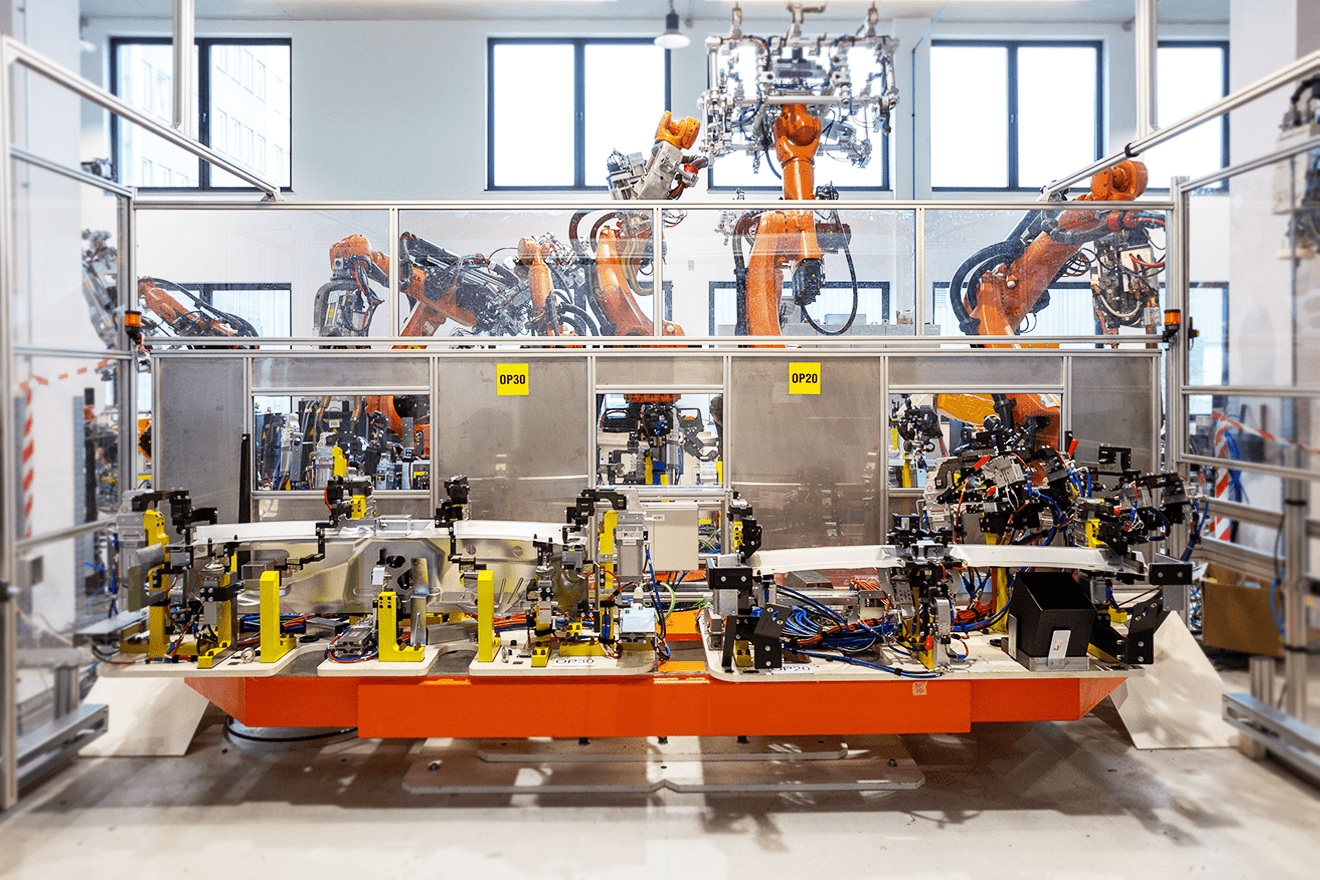

While starting the designing process of a production line or station or machine, we begin our work a detailed analysis of the assumptions for developing the best solution concept. This is the right response that the customer's individual needs require.

We create dynamic computer simulations of the main elements of robotic stations. This stage accelerates the further implementation of the project, minimizing the risk of possible errors during the actual implementation. Especially for the implementation of large production lines, we use virtual commissioning technology (production process simulation).

Our own mechanical workshop

We value independence and high-quality solutions. We have our own executive facilities in the AIUT mechanical workshop. This guarantees the efficient and timely implementation of even very complex projects for the construction of robotic lines and production stations. We carry out implementations in a turn-key model, offering support at every stage of investment and in the further product life cycle.

Multidisciplinary teams of engineers

The automation and robotics division is responsible for the implementation of our company's main projects. The department brings together over 500 competent, experienced engineers of various specializations including automation, electrics, mechanics, mechatronics and robotics. The interdisciplinary nature of our teams allows us to respond to the complex needs of customers, bringing international recognition to our company. Over 3000 completed implementations around the world are more than enough for a great reference.

Discover our potential

Among others, we design, manufacture and deliver:

- control and assembly stations (tightness, geometrical dimensions of electrical parameters)

- camera systems for quality control

- palletizing stations

- welding stations

- workstations for protective layers application

- glueing stations

- feeding elements for machines, handling presses

- machining stations for cast and plastic elements (chamfering, drilling, cutting)

- comprehensive design of a station

- implementation in own mechanical workshop

- tests at the AIUT headquarters

- on-site assembly

- commissioning and testing at the customer's location

Discover QURSOR. A dedicated production management system that allows you to save up to 70% of time spent planning. Thanks to the automation of production control processes (in terms of effective work stations planning, their robotization, use of appropriate machines) we gain a guarantee of smooth work while eliminating possible downtime and errors.

Manage your production efficiently based on:

- warehouse management modules

- machine and production management modules

- automated task delegation

Discover Maximo IT EAM solutions. Our goal is to improve the work of enterprises constantly, especially in the area of process control and maintaining the proper technical condition of devices. We implement modern solutions for maintenance services. They allow you to precisely manage the company's fixed assets infrastructure and plan properly tasks of technical inspections, machine maintenance, repair and warehouse management, or ordering parts and components - all this to ensure the plant to work without interruptions.

You gain:

- INCREASED PRODUCTION CAPACITY

- WORK SAFETY

- COST REDUCTION

- PRODUCTION REPORTS

- MANAGEMENT THROUGH AN APPLICATION

Discover F mobile robots - a new link in the intelligent production line. Equipped with advanced software and security systems, our intelligent AGV robots can be used as product transporters, as well as mobile production stations.

F mobile robots support the work of enterprises with the traditional-mannered supply of components needed at production lines. It can also act as an assembly platform integrated with the production line. At the same time, the vehicle itself has the ability to be fully integrated with a collaborative robot or other devices.

We provide solutions based on linear drives, pneumatic and hydraulic cylinders, servo drives and industrial robots of leading global manufacturers:

- ABB

- Comau

- Fanuc

- Kuka

- Motoman (Yaskawa)

- STÄUBLI

Warranty and post-warranty service

We provide our clients with a full warranty and post-warranty service for implemented projects, throughout the entire investment life cycle. This is a common complementary practice while working with AIUT. With the highest standard of services in mind, we provide the option of our qualified 24/7 support service.

Guarantee of business benefits (PRaaS)

We are a mature business partner. Our solutions allow enterprises to significantly optimize processes and reduce costs, as well as improve the quality of services provided. To support these declarations, a flexible approach to achieving business benefits as part of our projects is brought.

We offer various scenarios for cooperation - from technical support and consulting in traditional models, to sharing responsibility for achieving goals (KPIs) for specified areas in the PRaaS model - Process Responsibility as a Service - which guarantees business benefits for AIUT partners.