How warehouse automation drives success on Black Friday?

In this article, you'll discover:

-

what is Black Friday, and why is it so crucial for logistics?

-

what are the key benefits of warehouse automation?

-

which warehouse automation systems can help prepare your warehouse for the shopping frenzy?

-

what challenges arise when integrating new technologies into traditional warehouses?

-

how to handle logistics if your warehouse isn't ready for Black Friday and the sales season?

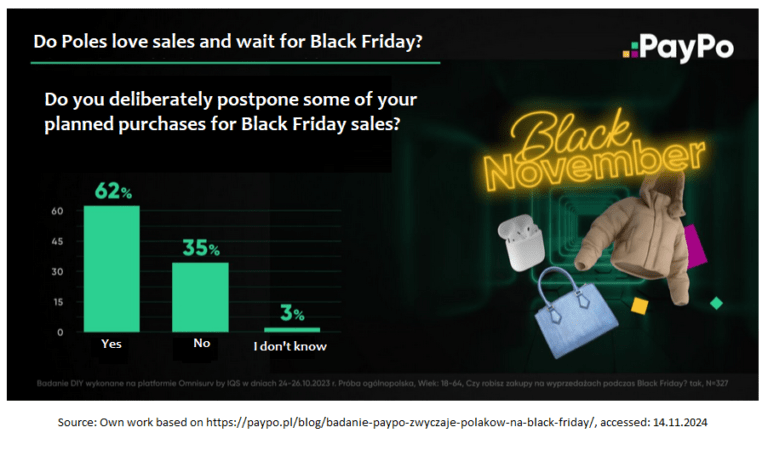

The end of the year marks the peak sales season. It's no surprise that the shopping frenzy in November and December translates into a highly demanding period for warehouses and logistics centers. Starting with Black Friday, the last Friday of November, the shopping marathon gains momentum, continuing until Christmas. According to a PayPo survey, 62% of consumers wait for Black Friday to take advantage of attractive discounts. This creates an opportunity for many businesses to boost their sales but also poses significant challenges for logistics and warehousing teams. To meet the surge in orders during this busy shopping period, warehouses, and distribution centers must be well-prepared. That's why logistics operations must gear up for the year's final quarter. In this article, we’ll explore advanced technologies and innovative warehouse automation systems that can help you stay ahead during this peak period.

Black Friday – what is it and why does it matter for logistics?

Black Friday is a day of sales and promotions, traditionally falling on the last Friday of November. In 2024, it will take place on November 29. The origins of this shopping holiday date back to the 1960s. One theory suggests that local media in Philadelphia, a city located on the northeastern coast of the United States, coined the term to describe the massive crowds flooding the streets to take advantage of post-Thanksgiving sales. Since then, Black Friday has been recognized as the start of the holiday shopping season. Today, retailers often extend special promotions beyond the day itself, offering deals throughout the week or even the entire month. Black Friday attracts consumers worldwide — both in physical stores and online. This makes the final quarter of the year a crucial period for retail, e-commerce, and logistics operations.

How to boost warehouse efficiency and prepare logistics for Black Friday?

For many businesses, Black Friday presents an opportunity to significantly increase sales, but it also comes with logistical challenges due to the sudden surge in order volumes. During such a busy period, reducing order fulfillment time and costs while eliminating errors that could lead to losses becomes crucial. To effectively manage logistics operations during this intense season, companies need reliable systems that optimize and automate warehouse processes and streamline supply chain management. Automated processes are essential because they deliver:

- uninterrupted logistics and production operations,

- shorter warehouse release cycle times,

- stable, repeatable processes with consistently high quality,

- faster order picking and preparation for shipment,

- operational continuity despite workforce shortages in the labor market.

Technologies supporting warehouse automation

The benefits of automation have driven more companies to adopt solutions that streamline warehouse operations. Among these technologies are Warehouse Management Systems (WMS), high-bay storage systems, buffer warehouses, automated production transport, Automated Storage and Retrieval Systems (ASRS), and digital twin technology. In the following sections, we will explore these automation solutions and explain how they enhance warehouse process efficiency, reduce operational costs, and support scalability during peak demand periods like Black Friday.

1. Warehouse Management System (WMS)

A Warehouse Management System (WMS) is advanced software designed to fully optimize warehouse operations. WMS enables the automation of key processes, including receiving, storage, order picking, and shipping, while providing real-time inventory monitoring. Implementing a WMS reduces the risk of errors, shortens order fulfillment times, and lowers operational costs. By integrating WMS with other systems, such as ERP or MES, businesses can gain complete control over the supply chain. This integration allows for data-driven analysis and the design of more efficient workflows. The data collected by a WMS supports informed decision-making, helping to optimize processes and eliminate bottlenecks in warehouse operations.

Learn more about WMS in our blog article: How does WMS improve warehouse management efficiency?

3. Automated High-Bay Warehouse

An automated high-bay warehouse is an advanced solution for efficient space management, particularly when dealing with a large volume of products stored in a limited area. With shelving systems that can reach several meters, or even over ten meters high, this technology maximizes vertical space utilization, increasing storage capacity without the need for physical expansion. High-bay warehouses often incorporate automated handling systems, such as stacker cranes, to ensure quick access to goods stored at higher levels. These systems minimize retrieval and storage time, streamline internal logistics, and enhance overall efficiency. Additionally, they allow for precise inventory monitoring, which is crucial for businesses with high product turnover and strict space optimization requirements.

Learn more here: Automated warehouse vs. traditional. Why do you need warehouse automation?

4. Buffer Warehouse

A buffer warehouse is a dedicated storage area designed to support dynamic inventory management, especially during periods of high demand. It serves as a temporary holding space for goods awaiting further processing or order fulfillment. This type of warehouse allows businesses to respond efficiently to sudden surges in orders while maintaining smooth logistics operations. By organizing goods based on anticipated production or sales needs, a buffer warehouse facilitates rapid order processing and minimizes the risk of operational downtime. When integrated with a Warehouse Management System (WMS), it provides precise inventory monitoring, resource allocation, and flexible process adjustments to meet changing operational demands.

Learn more about buffer warehouses in our blog article: Buffer warehouse — a breakthrough in process optimization!

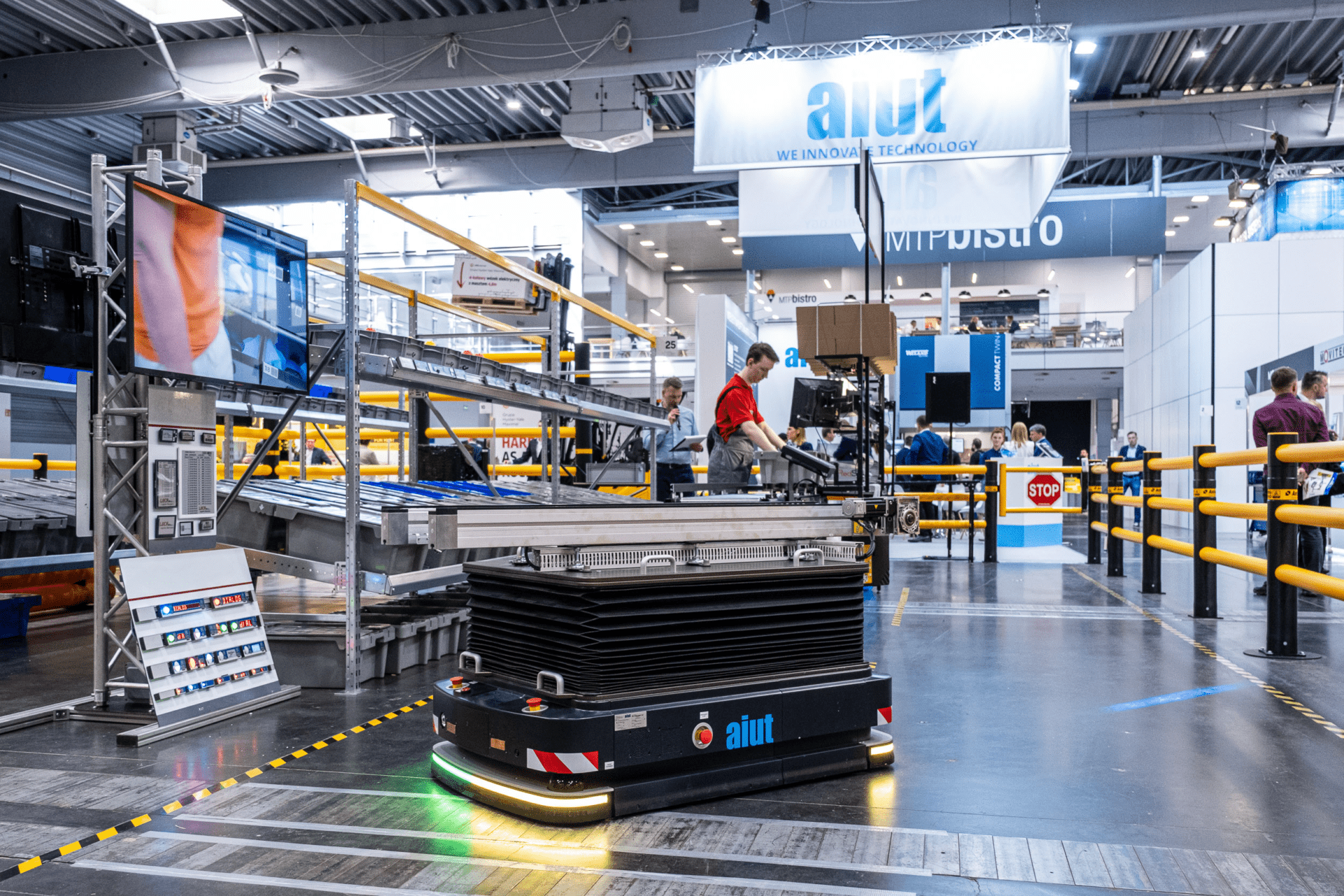

5. Automated Production Transport – Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are increasingly replacing traditional forklifts in both warehouses and production facilities. AMRs ensure safe and efficient transport of goods from one location to another, including the direct delivery of components to production lines. Operating 24/7, these robots significantly enhance operational efficiency for businesses. A great example of this technology is the F-series AMRs developed by our company, Aformic, and managed through the Qursor system. The scalability and flexibility of our solution allow businesses to quickly adapt their AMR fleets to new tasks, enabling them to respond effectively to changing market demands.

6. Conveyor Systems

Conveyor systems are a cornerstone of modern logistics and warehouse management, enabling the automation and optimization of goods flow. With various types of conveyors – belt, roller, and modular – businesses can efficiently and safely transport products between warehouse zones, production stations, or even across building floors. These systems not only accelerate order fulfillment but also reduce the risk of product damage and lower labor costs by minimizing manual handling. Conveyor systems are often integrated with advanced Warehouse Management Systems (WMS), allowing for full automation of material flow and real-time tracking of goods' locations. This integration boosts warehouse operation efficiency and ensures seamless adaptability to changing business needs.

Learn more about conveyor systems in our blog article: Conveyor Systems: The Key to Efficient Internal Transport, and explore our warehouse solutions offer here.

7. Automatic Sorters

Automatic sorters are advanced systems that significantly enhance the sorting process in warehouses and distribution centers, especially during peak periods like Black Friday or the holiday season. These systems automatically identify and direct products to the appropriate storage locations or directly to shipping zones. By utilizing automatic sorters, businesses can boost order fulfillment efficiency, reduce reliance on manual labor, and handle a much larger volume of orders in less time, which is crucial for the flexibility and effectiveness of the entire supply chain.

Discover how automatic warehouse sorters are revolutionizing logistics, and explore our warehouse solutions offer here.

Challenges of integrating new technologies in warehouses

Implementing modern automation technologies in warehouses requires careful planning and effective management. Transforming traditional workflows into advanced systems demands collaboration with an experienced partner to minimize the risk of disruptions to daily operations. Key aspects and challenges of warehouse automation and digitization include:

- ensuring compatibility of new solutions with existing infrastructure,

- training employees and its adaptation to new working methods,

- securing data generated by automated processes.

Partnering with experts ensures a smoother transition to an automated and digitized warehouse, enabling businesses to fully capitalize on the benefits of modern logistics solutions.

Warehouse automation – implementation

The decision to automate a warehouse largely depends on a company's readiness to invest, as automation can be applied to virtually any warehouse process. Implementing warehouse automation solutions can be done gradually, allowing for continuous performance monitoring and minimizing disruptions to warehouse operations. In some cases, a hybrid model that combines automation with manual handling may prove to be more efficient. This approach enables businesses to balance the benefits of automation with the flexibility of human oversight. Therefore, a holistic strategy for implementing automation and digitization is essential to successfully optimize logistics operations and improve overall efficiency.

What to do if your warehouse isn't ready for Black Friday?

If your warehouse or logistics operations aren't fully prepared for the upcoming Black Friday, don't worry — this is the perfect time to start planning for next year, including investing in automation. Explore AIUT's intralogistics and production transport offer designed to streamline your warehouse operations and reduce order fulfillment times. Now is the time to evaluate which areas you want to improve to enhance efficiency and better prepare your warehouse for future peak sales periods. Schedule a meeting with us today and take the first step towards optimized logistics operations!

Summary

Digitization and warehouse automation are essential for boosting sales and preparing businesses for high-demand events like Black Friday. The holiday shopping season poses significant challenges for the logistics industry, requiring rapid order fulfillment and reliable processes. Implementing modern automation technologies not only accelerates order handling, but also minimizes errors and significantly enhances the operational efficiency of warehouses.

Automate your warehouse with AIUT!

With years of experience and innovative technologies, AIUT helps businesses transform their warehouses and factories. Contact our experts today to prepare your warehouse for the demanding sales season and optimize your logistics operations. Let’s get your business ready for success!