How does WMS improve warehouse management efficiency?

In this article, you will learn:

-

What does the WMS (Warehouse Management System) market look like today?

-

What is a WMS Warehouse management software?

-

What benefits does the implementation of WMS system software bring to businesses?

-

Why is WMS solution essential for enhancing the potential for optimizing internal logistics processes?

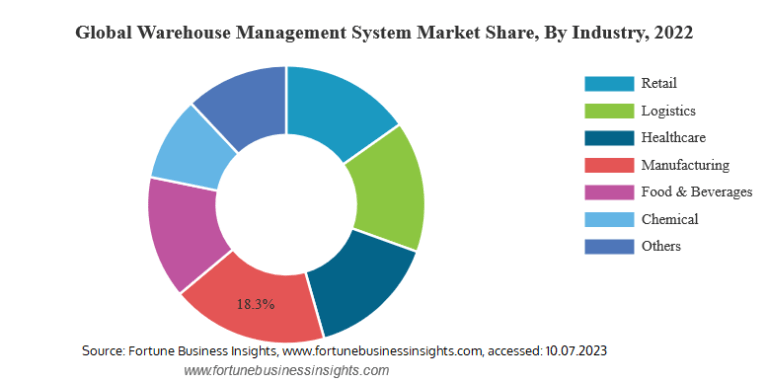

The global warehouse management system market

Modern businesses are facing increasingly significant challenges when it comes to managing their logistical processes. The growth of e-commerce, market globalization, rising customer expectations, and dynamic consumer trends require innovative solutions that enable effective warehouse and distribution center management. In response to these needs, WMS Warehouse Management Systems have become a crucial tool, allowing businesses to optimize their logistics processes, increase warehouse efficiency and flexibility, and streamline order fulfillment. According to the latest report published by Fortune Business Insights, the global WMS warehouse management software market reached a value of USD 2.75 trillion in 2022, and it is projected to grow to USD 7.30 trillion by 2030. This estimated growth in value underscores the increasing importance and widespread WMS rollout across various industries and sectors.

WMS definition. What are warehouse management activities?

A Warehouse Management System (WMS) is advanced software designed to assist companies in managing the flow of goods. The warehouse management solution enables precise monitoring and control of daily warehouse operations. Its responsibilities include the order fulfillment process, which encompasses goods receiving, inventory control, item location, and item dispatch. The WMS software gathers and analyzes data from these stages in real-time, allowing for more informed decision-making and the design of more efficient warehouse processes.

Warehouse management system benefits

The implementation of a suitable WMS system offers several advantages, making the management of goods flow and warehouse processes more efficient. Below are the benefits of warehouse management solution:

Increased warehouse efficiency

A WMS system automates many routine tasks. In addition to managing inventory levels and item locations, it also generates shipping documents. Furthermore, integrating with transportation management systems or ERP systems provides a broader perspective for warehouse management. This simplifies warehouse processes, allowing employees to focus on more value-added tasks, ultimately leading to faster product delivery.

More accurate warehouse inventory management and reduced human errors

WMS provides real-time updates on warehouse stock, helping to avoid issues related to stockouts or excess inventory. WMS software eliminates the risk of human order errors (e.g., in order picking) by automatically tracking and controlling inventory levels. This optimization of order processing minimizes costs, streamlines processes, and prevents order latency.

Faster order fulfillment and cost savings

Through monitoring and tracking features, WMS software enables faster order processing by helping determine the optimal picking routes. As a result, customers receive their ordered products more quickly, which increases their satisfaction and enhances a company's competitiveness. Efficient warehouse operations with a WMS allow for optimal product placement within available warehouse space. When dealing with products with limited shelf life, a WMS can help identify which items should be dispatched first, reducing warehouse labor costs, minimizing waste, and avoiding the need for additional warehouse expansion.

Summary of profits from WMS rollout

In summary, implementing a Warehouse Management System (WMS) offers advantages such as improved warehouse efficiency, accurate inventory management, reduced human order errors, faster order fulfillment, and cost savings, which collectively contribute to enhancing a company's competitiveness and customer satisfaction.

WMS integration with innovative solutions of automated warehouse processes

An increasing number of manufacturing companies are adopting solutions that automate the management of internal logistics processes. These solutions include autonomous mobile robots (AGV/AMR) and Automated Storage and Retrieval Systems (ASRS), such as high-bay warehouses, conveyor systems, automatic sorters, and many others, about which you can read more here. To begin implementing these solutions, a company needs to have WMS software and the ability to integrate the warehouse management platform with these automation solutions.

For example, AMR robots like Formica, offered by AIUT, can be fully customized to meet user needs and preferences and can be integrated with available industrial IT systems, such as Manufacturing Execution Systems (MES) and Warehouse Management Systems (WMS). Therefore, it is evident that a comprehensive warehouse management system is a crucial step in adopting more advanced warehouse automation solutions and harnessing their full potential. The key to success here is selecting the right integrator for these solutions and choosing the best WMS system provider.

Summary

A Warehouse Management System (WMS) is a fundamental tool in a company's management system. The warehouse management system optimizes crucial material flow processes specific to each warehouse. Automation of routine tasks, inventory management, goods flow control, and report generation enable more efficient management of product movement and enhances the productivity of warehouse processes. Furthermore, a WMS program minimizes the risk of human errors, monitors real-time inventory levels, shortens order processing, and allows for warehouse space optimization. Implementing a WMS system in companies is the first step towards further, more advanced warehouse automation.

Talk to our experts and learn more about the implementation of WMS software, and WMS integrations. Choose a warehouse management system with us!

We are one of the leading providers of advanced robotics and automation systems. We integrate our solutions with clients' Warehouse Management System software and also assist in selecting the top warehouse management software for them. We believe the right WMS is the beginning of our client's journey to efficient warehouse operation.