- Fuel terminal management system

- Solutions for the petrochemical industry

- IoT

- Solutions

Fuel terminal management system

Discover the solution that allows you to professionally manage a fuel terminal.

Intelligent managing

aTas - Terminal Automation System - is an intelligent platform for comprehensive management of a fuel terminal. It is created based on advanced IT and IoT (Internet of Things) technologies. The system works with filling and measuring devices. The solution speeds up identification procedures and ensures the highest level of terminal use safety.

aTas works with any number of external systems for efficient information exchange, including ERP, SAP or the Customs Office. The solution's functionalities and modules are configured to meet the client's needs and requirements.

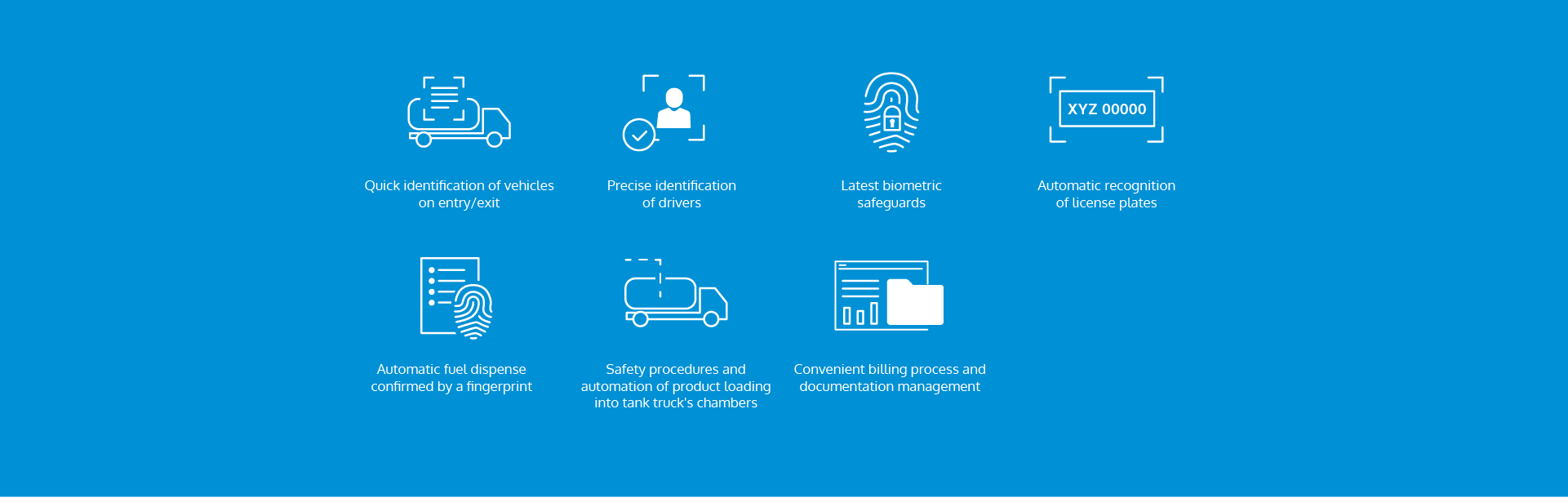

aTas enables quick identification of drivers and vehicles. It gathers and provides a set of documents necessary for fuel transport. The system also supervises safety processes related to loading and tank management. A vast reporting module enables detailed analysis and settlement of dispensed fuel.

aTas is one of the most complex solutions for fuel terminal management

Security and convenience

Our system allows for the automatic identification of drivers and vehicles while entering and leaving the terminal. aTas uses the latest biometric security for driver's unique fingerprint recognition, as well as the aLPR module for identifying truck's license plates.

Automated procedures

Based on the current delivery order and after the automatic verification of the vehicle and the driver, the system dispenses products for each chamber of tanker individually. The system verifies the maximum volume of chambers, the validity of driver’s and vehicle’s documents, and also predicts possible vehicle overloads right at the product disposition stage.

Functionalities:

- automatic vehicle and driver identification at the entry/exit gates

- automatic vehicle and driver identification on the loading ramp

- automation of the refuelling process enriched with a complete set of information for the driver - refuelling map: ramps numbers, distributors, filling codes

- documents validity supervision

- a set of documents generated as the truck enters the terminal

- automatic correction of issue documents

- chamber volume control

- chamber cleanness control

- tank management module

- reporting fuel status in all tanks

- full service of fuel additives

- consumption trends forecasting

- integration with any number of external systems

- integration with the SAP system at the level of order exchange and documentation

- real-time reports

- intuitive application and interface

What makes this product exceptional?

The modern approach to process automation in a company has allowed us to create an advanced solution for professional fuel terminal management. The system's functionalities and modules are configured to meet the client's needs and requirements.

aTas advanced instrumentation & control systems cooperate with tincture meters and other measuring devices, providing information on all processes (including signals during operation and alarms for abnormal events). This allows for proper actions to be taken immediately.

Moreover, the system verifies the available volume of truck chambers, the validity of driver’s and vehicle’s documents, and also predicts possible vehicle overloads right at the product disposition stage.

Our solution works based on the latest biometric security standards. Fingerprint readers and biometric kiosks can be used to effectively identify drivers.

We've developed a dedicated subsystem for identifying truck drivers and vehicles. Automatic recognition of the fleet and staff enables the service to be more efficient and the order to be completed in less time.

We implement the aTas system in a turnkey model. We carry out electrical supply and control projects, we are responsible for the installation and full commissioning of our solution.

- development of a technical concept

- development of control cabinet designs

- development of tooling designs

- development and commissioning of PLC and SCADA systems

- supply of fuel vapours recovery devices

- tests and full system startup

- technical support 24 hours a day, 7 days a week

- implementation of a biometric truck driver identification system

- implementation of a tank-truck number plates recognizing system

- implementation of various dedicated subsystems (e.g. reporting applications)

We provide our clients with 24-hour technical support, with a maximum response time of 1 hour

Automation speeds-up the implementation of processes, improving the company's position in a competitive market. New technologies embedded in system solutions bring a noticeable increase in the company's advantage.

Case Study

Challenge

Modernization of the fuel terminal. Construction of tank refuelling stations. Implementation of a dedicated facility and process management system. Baltchem S.A. Chemical Plant, Szczecin, Poland.

Our solution: aTas

Development of proprietary, multidisciplinary IoT ecosystem for aTas fuel terminal management: Terminal Automation System. The implementation was carried out in a turn-key model. As part of the implementation, AIUT specialists developed and implemented a dedicated system along with support for electronic data exchange with the SAP system.

AIUT tasks included:

- the technical concept of refuelling stations,

- multi-branch construction project together

- submission of documentation for the building permit

- detailed executive design,

- compliance assessment of the delivered I&C lines in accordance with local technical certification authorities.

As a contractor, we ensured wide supplies (industries: mechanical, electrical, I&C). We also performed comprehensive implementation and commissioning of software along with visualization of control systems for technological installations.

Benefits for the business:

- Increased market attractiveness of the facility

- Process automation and information exchange

- Improvement of the control process at the entry/exit gates and at loading stations

- Faster order processing

- Stricter safety procedures

- Increased facility management quality