Industrial Artificial Intelligence

From this article, you will learn:

Artificial Intelligence (AI) represents a dynamically evolving field in modern technology, and its impact on industry is becoming increasingly indispensable. Computer systems can create models and conduct in-depth analyses by utilizing advanced machine learning algorithms on ever-expanding datasets. As a result, they can make more effective decisions than humans and forecast events in later stages. Industrial Artificial Intelligence (Industrial AI), with its ability to detect hidden patterns and trends, and consider diverse factors, allows for a deeper understanding of complex manufacturing processes. This raises the question: how does it operate and in which solutions do AI techniques find application?

Industrial AI and machine learning – what are they, and when did they originate?

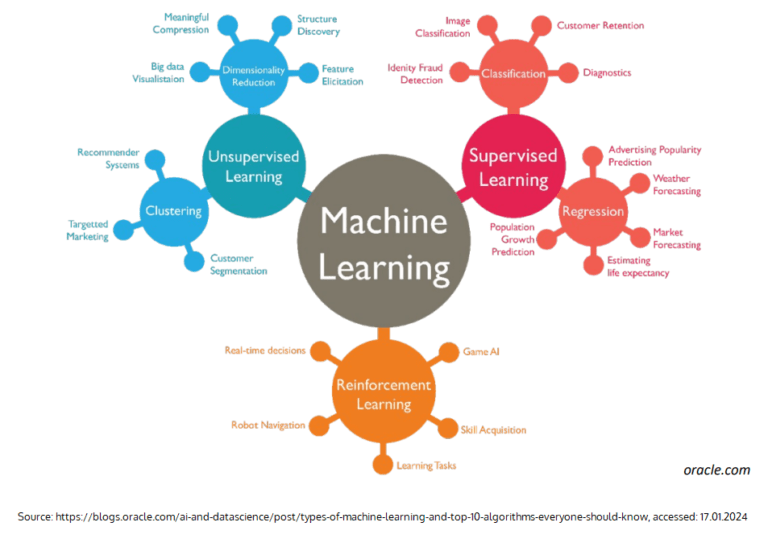

Artificial Intelligence (AI) is a broad term referring to computer systems capable of performing tasks that typically require human thinking. Machine Learning (ML) is one of its areas, focusing on developing algorithms and techniques that enable machines to learn from data and improve their behavior based on previous experiences. In the literature, it is divided into supervised learning, unsupervised learning, and reinforcement learning. Examples of applications for each of these fields are presented in the graphic below.

The term “Artificial Intelligence” was coined in the 1950s by American computer scientist John McCarthy, aiming to replace and shorten the terminology associated with the science and engineering of creating intelligent machines. However, its widespread adoption began gaining popularity only after 2010 when there was a demand for analyzing the increasing volume of data, and the computational power of computers was sufficient to carry out such analyzes. Learn more about the history of the emergence and development of AI here.

What is the value of industrial Artificial Intelligence?

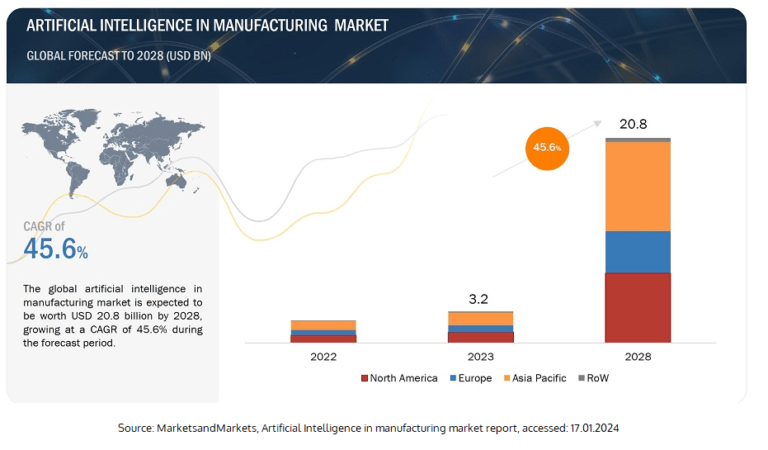

According to the MarketsandMarkets report, the global market value of artificial intelligence in the manufacturing sector reached $3.2 billion in 2023, with forecasts indicating $20.8 billion by 2028, considering an annual growth rate of 45.6%. Such substantial growth is made possible by "Big Data," enormous amounts of production data used by machine learning models and neural networks to enhance their capabilities. Additionally, the immense benefits of applying industrial artificial intelligence contribute to its increasing utilization in industrial automation solutions, meeting the growing demand in factories year after year.

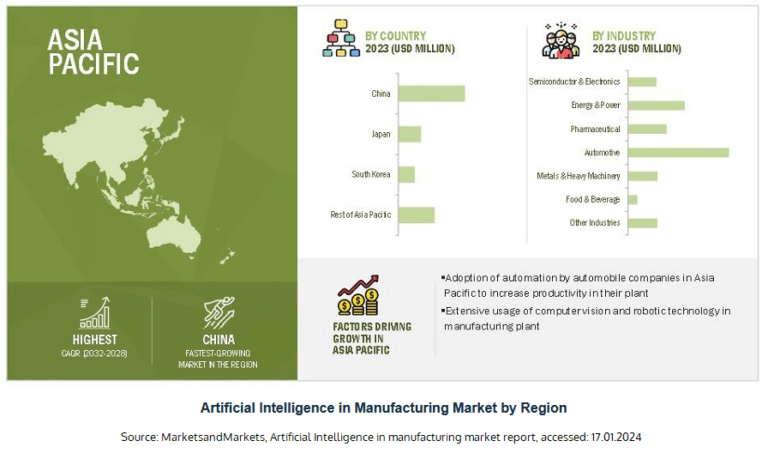

The report also indicates that Asia holds the largest share of the global value of AI. Among manufacturing enterprises in the region, the automotive industry stands out, which is associated, among other things, with the extensive use of computer vision technology and robotics in the production facilities of this sector. In these two areas, AI techniques are frequently employed, as described in the following paragraphs.

Big Data — how quickly do we collect data?

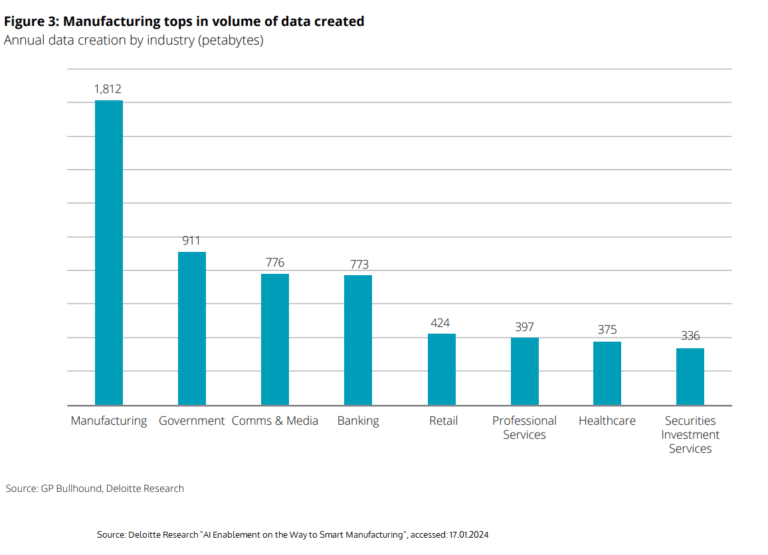

It has already been mentioned that artificial intelligence is advancing due to the continuously growing volume of data. Analyzing the Deloitte Research report titled “AI Enablement on the Way to Smart Manufacturing” the highest annual data volume – a staggering 1,812 petabytes (PB) – is industrial data representation associated with production processes (see chart below). To better visualize such large amounts of manufacturing data, it's worth recalling that 1 PB is equal to 1,000 terabytes (TB).

Complex manufacturing and the vast amount of industrial data make it increasingly challenging to make accurate and optimal decisions. Fortunately, intelligent technology comes to our aid, exploring data and utilizing it for further analysis, while our role will primarily involve supervision. In the presented Deloitte report on the application of artificial intelligence in manufacturing, 93% of companies believe it will be a key technology driving growth and innovation in this sector. With its assistance, factories will optimize industrial processes, yielding benefits both in terms of performance and cost savings.

Industrial AI's role — applications of machine learning algorithms

Automated intelligent robots

One of our solutions employing AI algorithms in automation and robotics is Qursor — an intralogistics platform, coupled with a fleet of autonomous mobile robots called Formica. Intelligent AMR Formica can learn and make decisions without operator intervention. They can dynamically adjust their routes, responding to changing environmental conditions such as obstacles or moving vehicles, thanks to advanced sensors and mapping technology. The Qursor software, managing them, allows for comprehensive control of all system parameters and their components. By implementing our intralogistics system, we ensure seamless integration with production management systems, warehouses (e.g., MES and WMS), and the factory environment – thereby guaranteeing uninterrupted and secure plant operation. Learn more about the Aformic solution here.

Implementing predictive analysis for production quality and efficiency

Artificial intelligence enables us to reduce production costs while maintaining the highest quality, even at the design stage. At AIUT, utilizing Virtual Commissioning (VC) technology for simulating processes and refining our solution allows us to shorten the actual deployment time at the customer's site. We develop custom software supported by artificial intelligence protocols, optimizing the work of industrial robots and autonomous mobile robots. Furthermore, VC enables the replication of robotic workstations, the production process, or even an entire production hall, using integrated industrial data from the entire production ecosystem, creating a digital twin. These advanced simulations, powered by analyzing algorithms, allow us to replicate real product behaviors, uncover production gaps, identify low-efficiency processes, improve machine and robot behaviors, and enable the monitoring of various process parameters. In short, they make the optimization of production processes much easier. As a technological partner, AIUT provides support and service throughout the investment lifecycle, ensuring data security among other aspects.

Internet of Things — predictive maintenance of machines and equipment

Machine performance data and equipment, collected through IoT (Internet of Things) sensors, is a highly valuable sources of information about the condition of machines. Artificial intelligence software works for our clients, predicting and preventing breakdowns (predictive maintenance). This allows them to be informed about an upcoming issue, enabling them to perform machine inspections earlier than scheduled. In this way, our clients can maintain production continuity, avoiding unplanned downtime in manufacturing.

Quality control in the industry with Deep Learning models

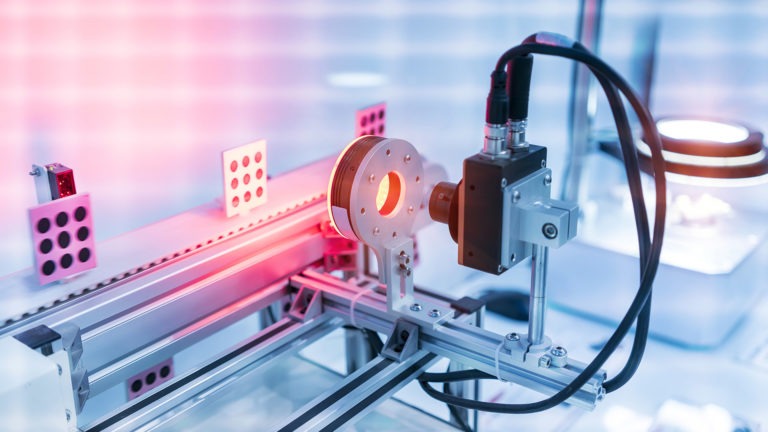

The implementation of industrial artificial intelligence allows for real-time data processing on the quality of produced items. Advanced vision systems and data analysis enable automatic detection of even the smallest defects that are invisible to the human eye. Thanks to these systems, we can reduce the number of defective semi-finished products and finished goods while increasing production efficiency and product quality. AIUT vision systems have a wide range of applications, serving as a quality control tool, making production and logistics processes more flexible, and enabling optical character recognition as well as 3D scanning. Learn more about their applications here.

Artificial intelligence's role in warehouses

Thanks to advanced predictive algorithms, artificial intelligence helps predict the demand for raw materials and supplies. This enables optimal inventory management, minimizing storage costs, and ensuring proper delivery planning. Companies can thus avoid excessive stockpiles and shortages, adapting more effectively to changing market conditions through flexible production.

Industrial AI capabilities beyond manufacturing plants! The role of AI in enterprise management.

WaterPrime – efficient utilization of thermal performance and water consumption analysis

IoT sensors, as part of the AIUT Smart City IoT solution, are used for remote monitoring of devices such as water meters or gas meters. Created by AIUT, the WaterPrime platform integrates sensor data and supports management and operational processes in Water and Sewage Companies. It consists of components covering resource and personnel management in the company, processing measurement information from various databases, and advanced data analytics based on machine learning tools and expert knowledge support. All of this is aimed at indicating the zone where a leak occurred, determining its location in space, diagnosing the states of technical elements of the water distribution system, or responding more quickly to any anomalies. Artificial intelligence technologies will ultimately help reduce water losses and energy consumption.

FuelPrime — Fuel Station Management and Leak Detection

One of AIUT's products is an advanced fuel leak detection system with real-time deep analysis for fuel stations. FuelPrime is a "big data" solution that enables fuel stations to achieve significant savings by eliminating fuel losses and, most importantly, reducing the risk of leaks. AIUT Fuel Prime operates based on a certified algorithm (SIR3 - Statistical Reconciliation Method) that analyzes data every minute and can quickly detect anomalies such as leaks, delivery shortages, inadequate/excessive metering, incorrect tank calibration, and more. Intelligent data analysis using artificial intelligence technologies allows for the detection of minimal fuel or water leaks – as low as 5 liters per day. Learn more about the FuelPrime solution here.

Summary

Artificial intelligence in the manufacturing industry is becoming not just a supportive tool but a true partner in optimizing processes. It is essential to meet the increasing demands of customers and stand out in the competitive landscape. Unlike humans, it effortlessly handles the analysis of vast amounts of production data. By leveraging it in various production-related aspects, we open new possibilities for productivity, flexibility, innovation, and safety in our factory, setting new standards. Learn more about the use of artificial intelligence in AIUT solutions here.

If you are looking for industrial AI in practical applications, let us know.

As an integrator specializing in industrial automation and robotics, we will conduct the automation of your production processes using cutting-edge industrial AI algorithms. We will tailor intelligent industrial applications to meet the needs of your manufacturing facility.