Maximize your plant's potential with F1 autonomous mobile robots. Check out the next-generation AGV capabilities.

A robot that's always ready to go

Do you care about improving your business results? Gain profit by automating logistics and transport processes in your enterprise. Use our advanced autonomous mobile robots to achieve better results. Discover F1, an intelligent transport vehicle designed to work continuously in a dynamic environment.

For the benefit of your business

Which way is the fastest one to deliver cargo to its destination? Our robot knows it. From now on, your crew can focus on other tasks. F1 makes decisions about choosing the optimal delivery route independently. By analyzing the environment, it can dynamically change its course depending on the existing conditions and suddenly emerging obstacles.

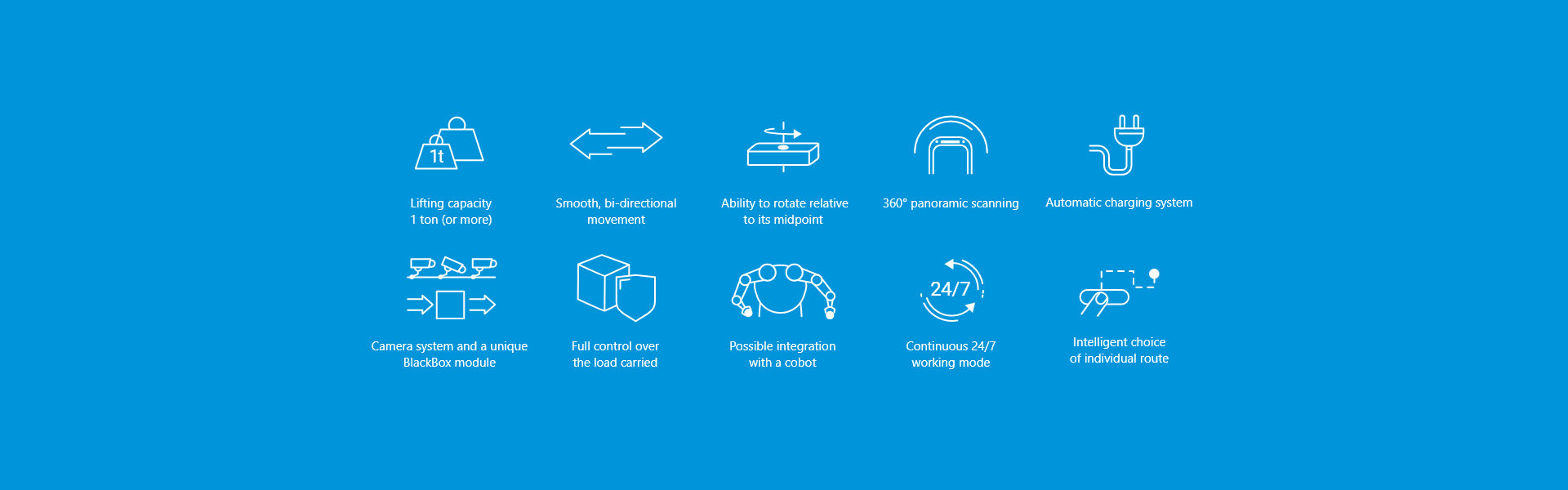

Eliminate accidents and collisions that are most often caused by traditional forklift trucks. Invest in proven, modern solutions for internal transportation. Maintain the continuity of plant operation and ensure the safety of your employees by choosing a self-propelled truck. This modern transport robot provides smooth, precise and careful transporting of goods, allowing the staff to work freely in the vehicle activity space.

Our robots can start working as the implementation just begins. Your decision is the only thing we're waiting for. Autonomous AIUT series F mobile vehicles are based on free navigation, which does not require changes in the infrastructure of the production plant. Thanks to this, we do not expose enterprises to additional implementation costs. Moreover, we reduce the time at which the robot starts its actual work to a minimum.

Improve your production line efficiency by easily optimizing and configuring your component delivery process to the assembly area. All these thanks to the introduction of F1 autonomous transportation vehicles.

The robots are working as planned, but a change is coming? Our solution allows you to adapt the logistics process to new demands easily. If your plant's production or working layout has changed, all you have to do is inform F1 by uploading the plan update to the system. Our robot is also able to independently create an updated map of the area on which it will be operating.

Relieve your employees by opting for maintenance-free and fully mobile solutions, such as a self-propelled cart. Let the crew focus on more demanding and complicated tasks than transporting resources within the factory.

Thanks to AIUT technology, our transporting robots can be adapted to the role of self-propelled production stations. When integrated with a cobot, they can perform specific tasks right on-board. In this way, we create new, independent units to make your production more flexible.

We provide complete technical support. Our engineers supervise the entire process of implementation and adaptation of robots to the needs of your plant. As part of the training, we will provide your crew with the necessary knowledge that will allow you to program a fleet of autonomous vehicles on your own.

Still not sure what decision to make? We adhere to the principle "Try before you buy". Use the pilot implementation option along with the test stage to see how our transport cart blends with your processes. In the next step, we will provide you with a detailed report and recommendations for further actions. This is the knowledge that will help you make your final decision.

You can always count on us. When you buy a F1 robot, you get a lifetime warranty on our product. We provide warranty and post-warranty inspections. We watch over the correct operation of the system. We provide remote diagnostics of machines to provide you with a solution to your problem as quickly as possible. Our technical consultants rapidly and efficiently diagnose and eliminate any problems that arise. They also instruct you on how to configure the working parameters properly. You don't have to worry about downtime. When using our supplies, you can be sure of a quick delivery of original spare parts or replacement industrial robots.

Discover the benefits and functionalities

F1 is an intelligent transport vehicle ready to work in any industrial space. Self-propelled trolleys ensure maintenance-free transportation of components from the warehouse area to the assembly area. They also can be used as mobile production stations. To achieve full consistency of performed activities, our robots are managed from a single order-processing system: AIUT Qursor. They can also be integrated with the customer's existing superior production management systems.

The extensive navigation system based on LIDAR technology allows the robot to create a virtual map of the work environment and track traffic in its vicinity to choose the optimal route (without interfering with the infrastructure of the plant). The vehicle makes decisions based on both real traffic and information from the fleet management system, adapting its response to the situation (it can slow down, stop, change the route, and others). F1 anticipates and bypasses high-traffic zones and excluded areas. The intelligent analysis allows the platform to predict various events.

Built-in advanced, certified safety systems guarantee full control of F1 operational area. The safety system allows staff to work freely near the vehicle's activity zone. Moreover, the Safety System detects non-standard obstacles on the designated route and gives full control over the transported load.

For maximum protection, F1 safety systems enable a 360° panoramic scanning around the vehicle. All obstacles below the laser beam level are detected by active bumpers located at the front and rear of the robot. The obstacles above are detected thanks to 3D cameras.

F1 is equipped with a unique BlackBox module, featuring a camera system and keeping a record of the vehicle's operating parameters. Also, an IMU module is implemented, verifying vibrations, overloads and external impacts - providing full insight into the operating history of the robot (with the ability to retrace events).

F1 is equipped with the latest generation of prismatic lithium-ion cells - successfully used in electric cars and others. Rechargeable battery along with a battery change system and automatic charging scenario ensures virtually uninterrupted operation of the plant. The batteries used enable long operating times (of up to 8-10 hours) and an extremely fast vehicle charging process.

F1 comes in two variants: with a lifting transport plate or with retractable coupling pins. In the first option, the robot verifies the transported load mass. For safety purposes during the operation, the load’s center of gravity is checked repeatedly.

F1 is a natural extension of the existing production and logistics management system in a company. Our solution can be fully adapted to customer needs and integrated with existing automation systems. For F1, it is possible to modify the parameters of the device in terms of meeting transportation requirements, loading and unloading stations and the level of process automation.

F1 mobile robots can cooperate with an advanced system of locating resources and people in the space of production halls. This gives the system a full view of the current state of any movable objects (forklifts, AGV-s, pallets, trolleys, people). As a result, a highly accurate traffic analysis, and a proper route choice become an object of further optimizations in terms of the arrangement of permanent elements or managing the personnel's work.