Automate transportation processes and let your staff perform more demanding tasks. Make F2 transport heavy loads for you.

Heavy load transportation robot

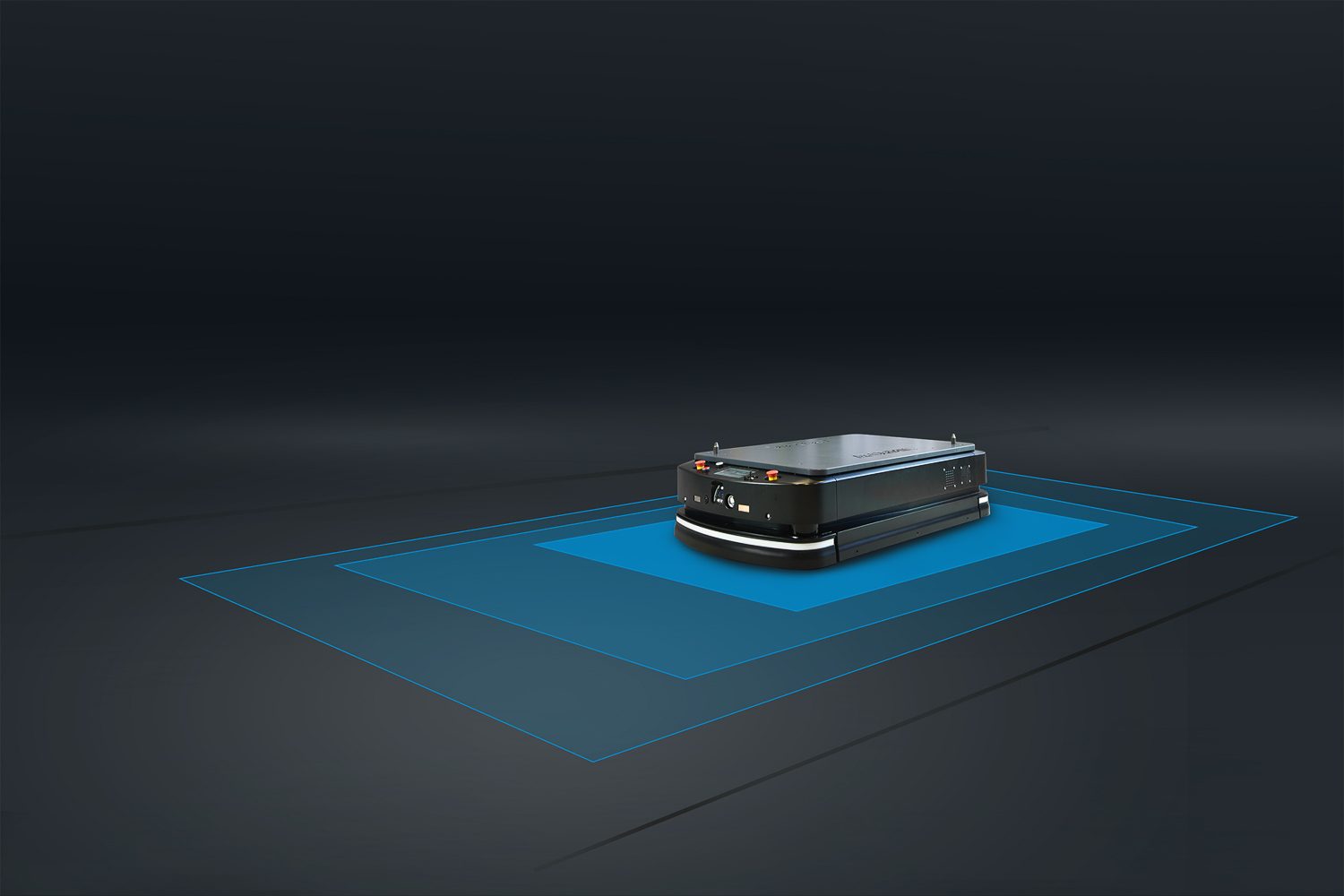

F2 is a self-propelled, intelligent mobile robot for transporting heavy loads of up to 1500 kg, equipped with pallet lifters. The robot picks, transports and delivers stock autonomously in a dynamic environment, providing a smart alternative to traditional forklifts.

Efficient intralogistics in your plant

- Do you wish to eliminate empty runs and ineffective routes?

- A speed-up for your processes is in demand?

- Would you like to improve the safety of traditional transportation methods?

- Do you have more challenging tasks for your crew?

Choose F2. Our autonomous mobile robots for the transport of EURO-pallet introduce a stable logistics process and ensure the safety of your crew and transported loads. As a result, the efficiency of intralogistics increases.

Efficient intralogistics in your plant

Create a safe working environment

Provide your crew with a safe working environment. Use F2 mobile robots to eliminate mistakes and accidents that seem inevitable during traditional heavy cargo transportation. Thanks to advanced, certified safety and vision systems, F2 moves throughout a dynamic environment without collisions, avoiding people and non-standard obstacles. Built-in weight distribution sensors give vehicles full control of heavy and high loads.

Unbind your staff

Relieve your employees with comprehensive solutions that automate light and heavy load transportation. By taking the task of collision-free large load delivery, F2 self-propelled vehicles will allow you to unbind the human resources involved so far and reassign them to more demanding and complicated tasks.

Let robots perform transportation - without mistakes and collisions

Invest in mistake- and accident-free transportation of heavy loads. Implement robotic transportation without operator's constant supervision needed and gain a stable logistics process. F2 robots adjust the delivery route to the actual traffic in the factory, avoid obstacles, and adapt the speed to the load's physical parameters - all this to deliver the load safely from the starting point to its destination.

Functionalities

- Dynamics and safety while transporting heavy and large loads

- Self-selection of the main or alternate route

- Natural navigation based on the actual surroundings

- Obstacle-avoiding and collision-free operation in the vicinity of people

- Prediction of heavy-traffic routes for effective path determining

- Control over heavy and high loads

- Bypass of exclusion zones

- Cooperation with elevators

- Certified security systems

- Robot's self-charging procedure in a docking station

- Remote, quick implementation without interfering with the enterprise current operation

- Quick and intuitive robot programming

Technical specifications

- 1.5 m/s - maximum speed, dynamically decreasing depending on the load

- 1500 kg load

- 8-10 hours battery life

- Automatic charging in a docking station or battery replacement available

- The ability to drive in both directions

- 360 ° rotation

- Wireless communication (IoT, SRD / 2G / 4G)

- Safe laser scanner

- Active bumper

- Emergency brake

- 3D camera, 3D ToF camera

- Ultrasonic sensor

- Mass sensor (strain gauge)

- Dimensions: 2000x1000x1000 mm

- EN1525, IEC / EN 60825-1 safety standards

- EN ISO 13850 machine safety standard

Discover the advantages and possibilities

F2 can be fully customized and integrated with any production system. The customization may include:

- Technical parameters, including dimensions and speed

- Navigation and location systems

- Functions: towing passive carts, lifting loads, linking with passive carts, taking loads off conveyors

- Drive control systems

- Obstacle detection solutions: ultrasonic sensors, vision systems, laser scanners

- Load distribution control

- Recording cameras

- BlackBox recording module with the possibility of event playback

- Human-machine interface

- Integration with current automatic systems, e.g. production stations

- Integration with working industrial IT systems, such as MES or WMS

- Fleet management control

The extensive navigation system based on LIDAR technology allows the robot to create a virtual map of the work environment and track traffic in its vicinity to choose the optimal route (without interfering with the infrastructure of the plant). The vehicle makes decisions based on both real traffic and information from the fleet management system, adapting its response to the situation (it can slow down, stop, change the route, and others). F2 anticipates and bypasses high-traffic zones and excluded areas. The intelligent analysis allows the platform to predict various events.

Built-in advanced, certified safety systems guarantee full control of F2 operational area. The safety system allows staff to work freely near the vehicle's activity zone. Moreover, the Safety System detects non-standard obstacles on the designated route and gives full control over the transported load.

For maximum protection, F2 safety systems enable a 360° panoramic scanning around the vehicle. All obstacles below the laser beam level are detected by active bumpers located at the front and rear of the robot. The obstacles above are detected thanks to 3D cameras.

F2 is equipped with a unique BlackBox module, featuring a camera system and keeping a record of the vehicle's operating parameters. Also, an IMU module is implemented, verifying vibrations, overloads and external impacts - providing full insight into the operating history of the robot (with the ability to retrace events).

F2 is equipped with the latest generation of prismatic lithium-ion cells - successfully used in electric cars and others. Rechargeable battery along with a battery change system and automatic charging scenario ensures virtually uninterrupted operation of the plant. The batteries used enable long operating times (of up to 8-10 hours) and an extremely fast vehicle charging process.

F2 comes in two variants: with a lifting transport plate or with retractable coupling pins. In the first option, the robot verifies the transported load mass. For safety purposes during the operation, the load’s center of gravity is checked repeatedly.

F2 mobile robots can cooperate with an advanced system of locating resources and people in the space of production halls. This gives the system a full view of the current state of any movable objects (forklifts, AGV-s, pallets, trolleys, people). As a result, a highly accurate traffic analysis, and a proper route choice become an object of further optimizations in terms of the arrangement of permanent elements or managing the personnel's work.

We will help you in a stress-free implementation, without any changes in the workplace itself

We provide complete technical support. Our engineers supervise the entire process of implementation and adaptation of robots to the needs of your plant. As part of the training, we will provide your crew with the necessary knowledge that will allow you to program a fleet of autonomous vehicles on your own.

Take advantage of a pilot implementation

Still not sure what decision to make? We adhere to the principle "Try before you buy". Use the pilot implementation option along with the test stage to see how our transport cart blends with your processes. In the next step, we will provide you with a detailed report and recommendations for further actions. This is the knowledge that will help you make your final decision.

Support always on time

You can always count on us. When you buy a F1 robot, you get a lifetime warranty on our product. We provide warranty and post-warranty inspections. We watch over the correct operation of the system. We provide remote diagnostics of machines to provide you with a solution to your problem as quickly as possible. Our technical consultants rapidly and efficiently diagnose and eliminate any problems that arise. They also instruct you on how to configure the working parameters properly. You don't have to worry about downtime. When using our supplies, you can be sure of a quick delivery of original spare parts or replacement industrial robots.