We have many years of experience in the practical use and supervision of chemical processes in industry. We conduct research, create and implement turn-key solutions, as well as modernize installations for clients in the chemical, cement and lime, food, petrochemical and energy market sectors. Our systems support a safe and efficient production and transport process, meeting environmental guidelines

Chemical and process engineering is the basis for the development of modern processing and petrochemical industry technologies. The demand for solutions in this area is constantly growing, which significantly affects the development and improvement process of the solutions offered in this area. This is one of our specialities.

Unique competences for your business

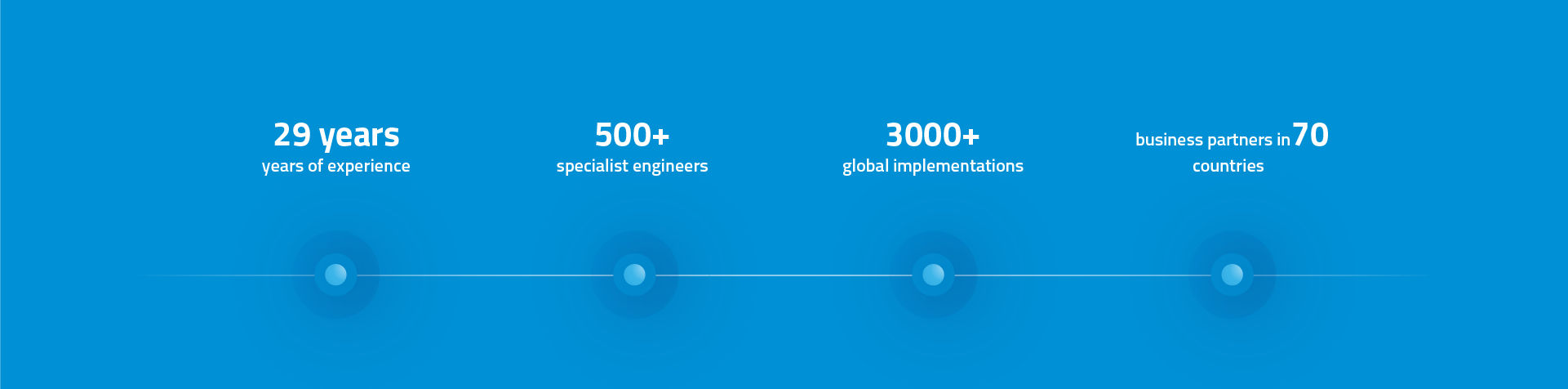

The knowledge and experience of AIUT team of specialists in the field of chemical and process engineering are turned into specific business solutions. We deal with the practical use of chemical processes in industry, combined with full automation and optimization of manufacturing processes on a macro-scale. We implement projects according to international norms and standards, taking into account the specific requirements of foreign investors.

- we develop new market products

- we are responsible for design and implementation of safe and efficient solutions

- we implement installations to improve production processes

- we modernize existing industrial installations

The range of products and services of the Continuous Process Automation - Chemicals department includes technologies of inorganic and related chemistry, as well as fuel industry.

Main areas of operation. Explore AIUT capabilities

Among others, AIUT designs and implements:

- installations for the production of sulphuric acid and sulphur compounds

- installations for the production of granulated sulphur

- installations for the production of artificial fertilizers

- installations for the production of other inorganic compounds

- installations for fuel depots/terminals (loading and unloading fronts)

- petrol vapour recovery installations

AIUT for sulphuric acid factories:

- absorption towers I and II

- oleum towers

- drying towers

- heat exchangers

- sprinkler systems for absorption towers

- systems of process gas recovery boilers composed of: an evaporator, a boiler drum, steam superheaters, economizers

AIUT for the fuel industry:

- turn-key fuel vapour recovery installations (OPB/VRU)

- installations for volatile compound vapours freezing off

- projects and concepts for the construction and modernization of fuel depots

We are responsible for comprehensive service of the investment process, including:

- technical, as well as technical and cost concepts

- detailed design

- license documentation

- as-built documentation

- construction projects for obtaining a building permit for new and modernized installations

- technological

- mechanical and structural

- construction and structural

- measurement and automation

- electrical

- software

I Ground-level projects, including:

- process optimization or selection

- selection of apparatus and equipment

- guidelines for commissioning and operation

II Detailed designs, including:

- construction documentation

- apparatus detailed and acceptance documentation

- selection of typical equipment

- pipeline detailed and acceptance documentation

- installation documentation

- commissioning and operating instructions

III As-built documentation,

performed on the basis of current European and international standards, adapted to the investor’s requirements, while maintaining good engineering practice.

Research. Development. Solutions

Process engineering is an important part of new technology. The market of solutions for the automation of continuous processes in the context of chemical processes is dynamically growing and requires suppliers to manage safety areas and meet environmental standards. At AIUT, we have advanced knowledge concerning, among others, the construction of apparatuses and entire process lines, in which chemical processes are carried out. This allows us to respond precisely to our customers’ needs. We develop and test our projects in the research and implementation laboratory of AIUT in Gliwice.

To embrace EU directives

The European guidelines on the environmental protection underline the importance of measures to prevent and reduce air pollution. The European Community seeks to reduce emissions of harmful substances into the atmosphere. Legal action in this area is taken in order to protect the health of citizens and the environment, while constituting an important part of the policy for combating adverse climate change.

Fuel vapour recovery systems at fuel stations and terminals

AIUT installations for fuel vapour recovery reduce the release of harmful substances into the atmosphere during the refueling of motor vehicles at fuel stations and terminals.

The recommendations contained in the two EU directives are intended to reduce VOC emissions from fuels and solvents, which are emitted during the filling or unloading of road tankers and rail tankers for the transport of dangerous goods and during the refueling of vehicles at fuel stations.

The solutions in the second stage are fuel vapour recovery installations. Their task is to capture the fuel vapour released during refueling and transfer it to the storage tank. The process is supported by control activities in accordance with European standards, consisting of regular performance checks on the equipment used.