Top 5 global robotics trends for 2025

From this article, you will learn:

-

what robotics trends are worth considering in 2025?

-

how will new technologies impact the future of your company?

Change is an integral part of our lives, and technological progress continuously provides factories with new opportunities. Companies that stay up-to-date with trends and implement innovative technologies increase their operational efficiency, reduce costs, and gain a competitive edge. Actively analyzing and continuously updating strategies allows businesses to better adapt to a dynamically changing reality. As the year draws to a close, it’s time for summaries and reflections on the technologies implemented in production facilities. This review allows us to assess what has delivered the expected results and what requires further optimization. By doing so, we can plan the automation of additional processes, laying the groundwork for an even more efficient operational strategy that will accelerate the company’s growth in the coming years.

This raises the question: what robotics trends are worth investing in for 2025? The answer lies in technological innovations that will not only shape production environments in 2025 but will also become an essential part of factories in the years to come.

Robotics trends that will revolutionize the way factories operate in 2025

1. Artificial Intelligence (AI) and Machine Learning

Artificial intelligence is increasingly becoming a part of our daily lives, emerging as a key element in the development of nearly every field. Thanks to advanced algorithms, it is possible to process vast datasets, uncover patterns, and make more accurate decisions. Moreover, the speed at which AI analyzes data allows for real-time reactions and decision-making. Additionally, machine learning algorithms enable the prediction of future events, such as machine failures, and the creation of scenarios that help prevent downtime.

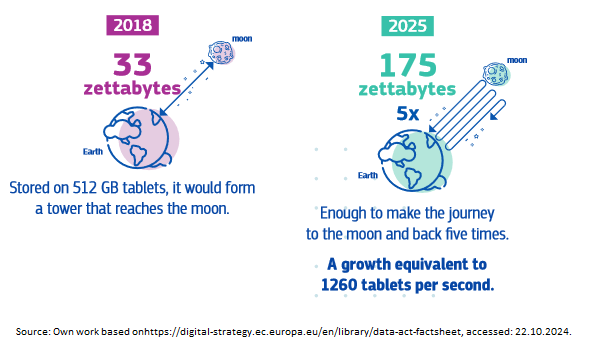

According to a European Union report, in 2018, people generated 33 zettabytes of data, and forecasts suggest that by 2025, this number will rise to 175 zettabytes. A fivefold increase in just seven years shows how vast data resources can be utilized. However, without the support of advanced algorithms, processing such volumes of information in a timely manner would be impossible. Therefore, the AI trend will continue to evolve, with new and improved AI solutions in the industrial sector constantly emerging. To explore this topic further, we invite you to read the article: “Industrial Artificial Intelligence.”

2. Industrial robots, including mobile manipulators

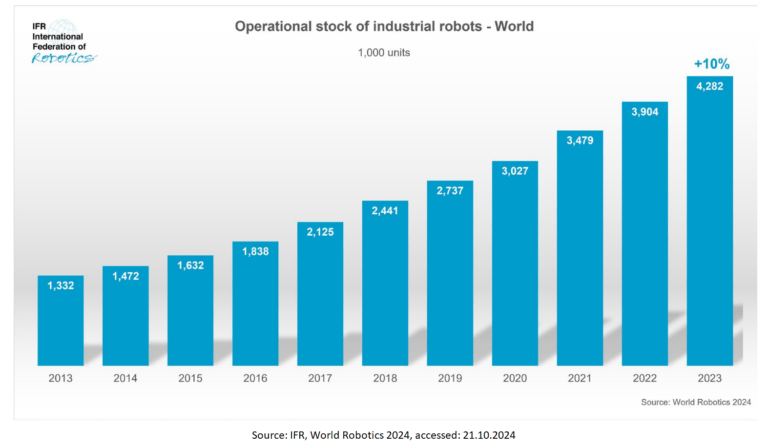

The World Robotics 2024 report, published by the International Federation of Robotics (IFR), states that 4,281,585 robotic units were operating in factories in 2023, marking a 10% increase compared to the data from the previous year's report. The latest IFR study shows that 70% of deployed robots were installed in Asia, while Europe accounted for 17% of the total. The report includes statistics on industrial robots, based on the definition of a robot outlined in the international standard ISO 8373. Specifically, IFR members provide data on robots used for automating the industrial sector, which:

- are reprogrammable, meaning their movements can be reprogrammed without altering the mechanical structure,

- are multifunctional, meaning they can perform a variety of tasks,

- operate in at least three axes,

- can be mounted on a mobile platform.

Three basic types of robots based on robotic arm kinematics

Articulated robots

Articulated robots are built from a series of arm segments and joints that, as the name suggests, create articulation points. Their design allows for movement in multiple directions, giving them a high degree of maneuverability and the ability to perform programmed tasks. The joints are typically classified into two types: sliding joints, where movement occurs along one axis, and rotary joints, where movement occurs around a single axis. Articulated robots are commonly used in the automotive, aerospace, electronics, and heavy industries for assembly, welding, and painting processes.

Delta robots

Delta robots, often referred to as spider robots, are designed to perform extremely fast and precise movements. Their unique structure — three parallel arms attached to a base mounted overhead — makes them ideal for installation above conveyor systems. Delta robots are widely used in the pharmaceutical and food industries for packaging and sorting, as well as in the electronics sector for assembling lightweight and delicate components, such as microprocessors. Combined with vision systems, they can sort items on conveyor belts according to predefined criteria, such as shape, color, or size.

SCARA robots

SCARA robots (Selective Compliance Assembly Robot Arm) offer agility and precision similar to that of delta robots. They typically consist of two or three arms connected by joints, capable of moving horizontally and vertically. At the end of the arm is a specialized tool designed for handling various products, such as a gripper. Like delta robots, they are used in assembly, packaging, and sorting. However, they stand out due to their compact design, which allows them to be used in confined spaces.

Learn more about industrial robots in our blog article: “Industrial Robots in Production Automation”. We also encourage you to explore our range of solutions in industrial automation and robotics.

MoMas — Mobile Manipulators

A growing trend in robotics that will continue to evolve in 2025 and beyond is the development of mobile manipulators, commonly referred to as MoMas. These industrial robots are the result of combining the tasks performed by a robotic arm, such as gripping, lifting, or moving objects, with the ability for robots to navigate through space. MoMas consist of an AMR (Autonomous Mobile Robot) integrated with a robotic arm equipped with a suitable tool. Mobile manipulators can perform pre-determined production tasks onboard or retrieve components from the production line or warehouse. This flexibility allows for the automation of material transport to any location, introducing a new level of efficiency in production and warehouse management.

Examples of mobile manipulators include the AMR F series robots designed by our company, Aformic. These robots can be used to place products on an autonomous platform or to unload them. In addition to their transport functions, they perform assigned tasks, bringing a new level of efficiency to production and warehouse management.

The image below shows Aformic’s AMR FP3-2 robot. You can find more information about MoMas and other models of our AMR robots here.

3. Cobots

Cobots, or collaborative robots, are typically static robots that are part of a production line. Unlike traditional industrial robots, which usually operate in isolated zones, cobots can safely collaborate with humans at their workstations. They are also simple to operate and program, enabling their quick deployment in various production processes. Their design makes them easy to move, allowing them to adapt to changing production needs. By utilizing technologies such as artificial intelligence, vision systems, and the Internet of Things (IoT), cobots can integrate with modern production systems, supporting the concept of Industry 4.0 and enhancing process integration. These advantages make cobots a key player in the flexible and automated production of the future. Learn more about collaborative robots here.

How do we know that robots will be an important industrial trend in 2025 and beyond?

Robots can work 24/7, which allows for a significant improvement in process efficiency. Automating tasks such as assembly, welding, or packaging increases the pace of production without compromising quality. Robots perform tasks with high precision and repeatability, minimizing the risk of errors. They can also operate in extreme conditions, such as high temperatures, polluted, or toxic environments, improving safety by allowing human workers to be assigned to other tasks. Modern robots quickly adapt to various tasks, making them ideal for production environments with changing needs. The combination of mobile AMR robots with integrated robotic arms creates so-called mobile production stations, enabling robots to move around the factory and perform specific tasks onboard.

4. Digital Twin

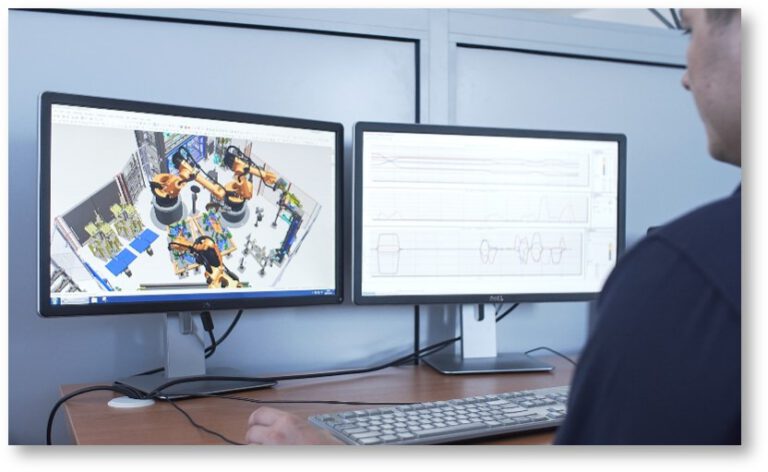

The digital twin will be one of the key trends in 2025 due to the increasing need for companies to better manage, monitor, and optimize their operations in real-time. Digital twin technology, which involves creating virtual models of physical objects, processes, or systems, enables companies to predict failures, optimize production processes, and test different scenarios without risking interference with actual operations. Combined with the advancement of Internet of Things (IoT) sensors and artificial intelligence, digital twins allow for precise real-time monitoring of machine and process conditions, increasing efficiency, reducing maintenance costs, and minimizing downtime. Given the growing complexity of production and the need for flexibility, the digital twin is becoming an essential tool in the pursuit of full industrial digitalization and the realization of Industry 4.0 and future revolutions.

Learn how at AIUT, we use virtual commissioning and digital twin technology when developing automation and industrial robotics solutions for our clients.

5. Humanoid robots

Humanoids are robots designed to resemble humans in appearance, structure, and movement. Their construction often includes features such as a head, torso, arms, and legs, enabling them to perform tasks and movements typical of human posture. Humanoids may also have faces capable of expressing emotions, as well as hands capable of manipulating objects in a manner similar to humans.

Humanoid robots market

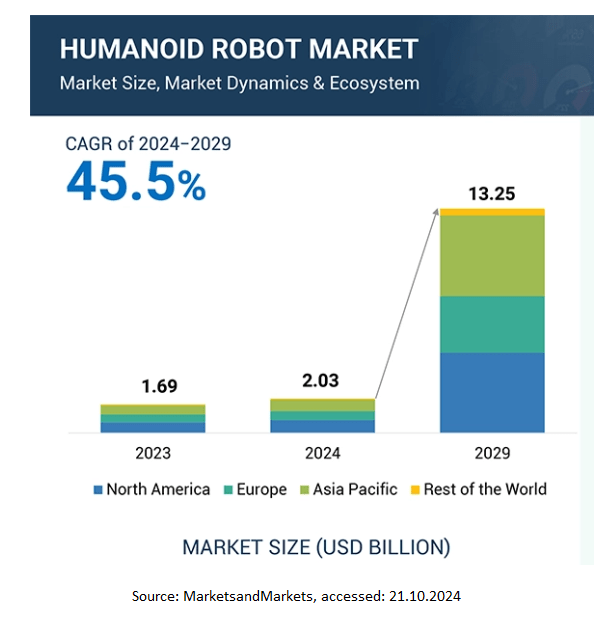

A chart in the MarketsandMarkets report illustrates the projected growth of the humanoid robot market from 2024 to 2029. In 2024, the market value is expected to be USD 2.03 billion. Forecasts indicate that by 2029, the market value will reach USD 13.25 billion, with a compound annual growth rate (CAGR) of 45.5%.

The report highlights the following factors driving the growth of the humanoid robot market:

- advances in artificial intelligence (AI) and machine learning (ML),

- improvements in humanoid robots, which are gaining increasingly advanced features,

- the growing use of humanoids as educational robots.

However, the report also identifies factors limiting the growth of the humanoid robot market:

- high initial investment costs and R&D expenses required to develop humanoid robots,

- safety concerns that limit broader implementation of humanoid robots.

Will humanoid robots replace humans in factories?

Humanoid robots have the potential to replace workers in certain tasks in the future, particularly those that are repetitive, physically demanding, or dangerous for humans. The World Robot Conference 2024 in Beijing showcased humanoid robots that made a huge impression, offering a glimpse into the future direction of the industry. However, at this time, full automation of production processes with their involvement is not expected to become a reality in the near future. It is estimated that the first fully autonomous humanoid robots won't be available until at least 2050. Currently, their high implementation costs and technological limitations, such as short battery life, make them neither fully cost-effective nor efficient. Rather than completely replacing humans, a more likely scenario is one where humanoids work alongside employees, enhancing productivity and safety.

Summary

The year 2025 will bring a revolution in robotics, driven by technologies such as artificial intelligence, cobots, industrial robots, mobile manipulators, and digital twins. Implementing these innovations will allow companies to increase efficiency, reduce downtime, and optimize production processes. Preparing for these changes now will give your company a lasting competitive edge and readiness for future challenges.

Is your company ready for the upcoming trends in robotics?

Don't wait for the competition to get ahead – see how we can automate your production processes together!