Logistics reaching clouds – automated high-bay warehouse

With technological advancements and increasing market demands, innovative and automated logistics solutions are indispensable. Traditional inventory gathering and management methods are becoming less efficient in the face of growing supply chain complexity, product diversity, and customer needs. Hence, logistics automation and digitization of internal warehouse processes become an integral part of building competitive advantage for businesses. Success in this realm requires implementing new business concepts that allow for more efficient material handling, and production management, and selecting the right technological partner. One of the primary trends in this area is investment in automated high-bay warehouses and internal delivery robotics technology, which enable optimization of production processes.

Warehouse automation — what does it involve?

Warehouse automation is the process of integrating robotics technology or other advanced mechanisms into warehouse operations. This includes implementing advanced technologies such as industrial robots, artificial intelligence (AI), machine learning, sensors, and software systems to streamline and improve inventory management efficiency. Examples of these solutions are high-bay warehouses.

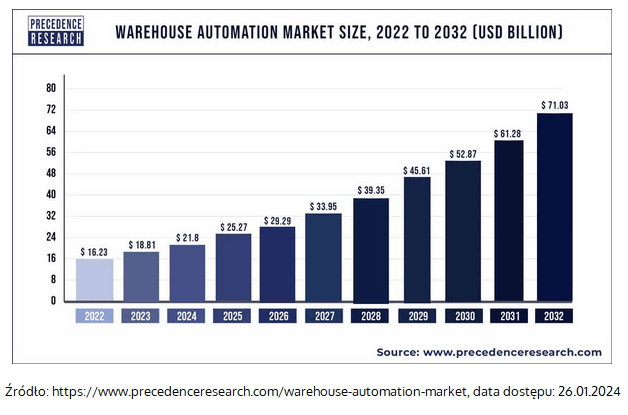

According to the Precedence Research report, the global warehouse automation market reached $18.1 billion in 2023, and forecasts suggest it will grow to around $71.03 billion by 2032, with an average annual growth rate of 15.91%. This study only confirms that there is a demand for automated logistics solutions, and companies are increasingly turning to them.

Automated high-bay warehouse — how does it work and what benefits does it bring?

An automated high-bay warehouse is an advanced logistics system that utilizes cutting-edge technologies such as artificial intelligence, robotics, and process automation to optimize the storage solution, movement, and retrieval of goods. Its main characteristic is its ability to store large quantities of products in a small space by increasing storage density, allowing for maximum utilization of available warehouse space. Find out what we can do for you in this area.

Benefits of automated high-bay warehouses

The advantages of automated high-storage warehouses, built on automated storage and retrieval systems (ASRS), are outlined below.

Optimal use of warehouse space

Efficient utilization of warehouse space (room height even up to 50 meters high), resulting into space savings, is a key factor favoring automation. Traditional warehouses often fail to efficiently use space, leading to prolonged cycle times and an inability to increase storage capacities. Conversely, automated solutions, such as high-bay warehouses equipped with conveyor technology, stacker cranes, pallet shuttle systems, etc., enable full utilization of the facility's volume, ensuring continuity of logistics processes and unprecedented operational efficiency increases.

Increased inbound and outbound dynamics

Advanced systems ensure the shortest possible time for order picking and preparation for shipment, resulting in better and faster order processing. These solutions, leveraging technologies like artificial intelligence, can predict purchasing decisions based on real-time and historical data, initiating order preparation before the customer completes the purchase. Consequently, shipments are frequently delivered to customers the next day.

Operational efficiency growth and greater flexibility

Modern high-bay storage operates continuously, fulfilling orders around the clock, 24 hours a day, providing companies with a significant competitive advantage amid increasing order volumes. Automated storage systems are easily scalable and adaptable to changing business needs and requirements, facilitating quick adaptation to evolving market environments.

Minimization of human errors

Another advantage of high-bay storage pertains to employee safety and ensuring consistent, high-quality, error-free order fulfillment. The repeatability of operations within specified timeframes and quality standards, ensured by warehouse technology, enables the orderly preparation of assortments in just a few seconds. Such results are unattainable with traditional material handling methods. Additionally, by leveraging advanced logistics automation and industrial robotics systems, workers can be reassigned to more responsible and safer tasks. Automation also addresses the labor market challenges faced by the manufacturing and logistics industries.

Reduction of operating costs

While the initial investment may be substantial, automated high-bay warehouses contribute to a significant long-term reduction of operational costs by enhancing the facility efficiency of logistics processes. Optimization of warehouse space and precise inventory management also minimize losses and costs associated with excessive accumulation or improper placement of goods.

Technologies constituting automated high-storage warehouses

Artificial Intelligence (AI)

The necessity for effective management of processes in the logistics chain has led to a growing demand for automated warehouses that are increasingly intelligent, inherently unmanned, and error-free. AI systems analyze data regarding inventory, orders, and the flow of goods, enabling optimization of warehouse processes and forecasting customer needs. Implementing warehouse technologies supported by machine learning and artificial intelligence aims to streamline operations and become a decisive factor in a company's position in the competitive market. Increasingly complex artificial intelligence algorithms are utilized for analyzing vast amounts of data related to orders, picking processes, transportation routes, and inventory statuses generated in warehouse management software – and to detect specific customer behavior patterns based on this data. Such operation allows adjusting supply to the current demand in advance and, among other things, reducing the quantities of unnecessarily stocked products on warehouse shelves. More about AI in manufacturing applications can be found in the article “Artificial Intelligence in Industry".

Advanced vision systems

Automated warehouses enable more efficient order processing. This is achieved, among other things, through remote sensing provided by various types of sensors and vision systems. Based on the gathered data and analysis of historical patterns, AI-supported logistics management systems enable the acceleration of operations, the generation of performance evaluations, and the assessment of warehouse efficiency.

Delivery robotics

Autonomous Mobile Robots (AMRs) are increasingly responsible for streamlining cargo delivery operations in warehouses and manufacturing facilities. In the case of our solution, we refer to the advanced intralogistics system Qursor, which allows comprehensive management of internal logistics processes, and a fleet of AMR Formica mobile robots. We integrate the solution with any customer's Manufacturing Execution System (MES) and Warehouse Management System (WMS). As a result, Qursor not only continuously analyzes the dynamic work environment, but also the current hierarchy of tasks assigned by the superior system, flexibly responding to sudden production needs. This helps prevent downtime and increases enterprise or warehouse efficiency.

Digital twin

Automation of inbound, sorting, picking, and outbound warehouse processes, increased efficiency and safety at work, error-free process execution, better inventory control, and the ability for predictive analysis – these are the qualitative changes offered by modern warehouse solutions. By utilizing Digital Twin technology and Virtual Commissioning, we can assess the investment – an automated warehouse project based on key profitability indicators and improve the validation process of systems, eliminating unforeseen errors and bottlenecks before starting the investment construction. With our digital deployment platform, we can simulate warehouse operations for the client after implementing specific warehouse automation systems. Thus, the company already knows during the project phase what measurable benefits it can achieve through the investment.

Summary

Warehouse skyscrapers are not only an innovative logistic solution but also a crucial element of future warehouse infrastructure. Utilizing automated warehouses and advanced technologies enhances the efficiency, flexibility, and competitiveness of logistics operations. Faced with increasing market demands and the growing complexity of supply chains, investing in automated high-bay warehouses can be a pivotal step toward success and long-term profitability in logistics operations.

Invest in a high-bay warehouse today!

As an integrator of automation and robotics solutions, we are responsible for the comprehensive implementation of automated warehouse projects and intralogistics systems. By combining unique engineering competencies, we build advanced solutions for industry and logistics, tailoring projects to meet individual customer requirements.