From Click to Delivery: E-commerce warehouse automation

In this article, you will learn:

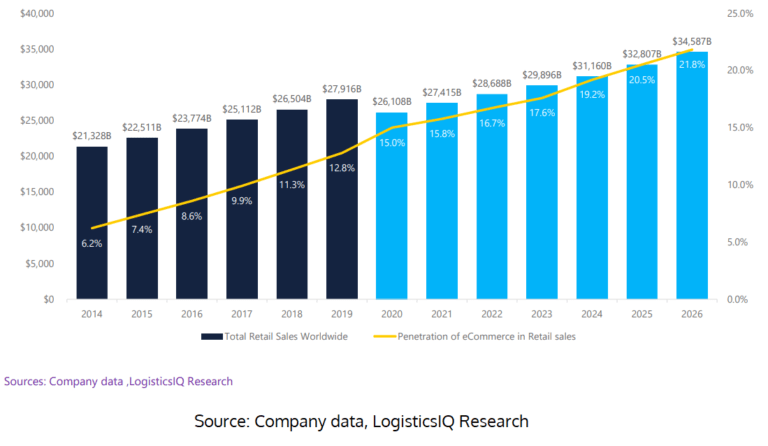

In the digital age, the rapid development of e-commerce has become a turning point for the global economy, transforming consumer behavior and redefining the landscape of e-commerce logistics and supply chains. As online shopping gains popularity, one of the most significant transformations is taking place in the sphere of warehouse operations. The expansion of e-commerce not only drives the demand for more efficient logistics but is recognized as the main engine of warehouse automation, pushing the industry towards innovative solutions and more efficient, faster operations.

E-commerce growth as catalyst for change: Warehouse Automation Statistic

The e-commerce boom, accelerated by technological progress and changes in consumer preferences, especially during and after the pandemic, has led to an unprecedented influx of online orders. This growth is not temporary, but directly indicates the future direction of shopping habits worldwide. The convenience of online shopping, combined with the expectation of quick deliveries, has set a new standard for warehouse efficiency. To meet this challenge, companies are turning to automation, and implementing modern warehouse solutions.

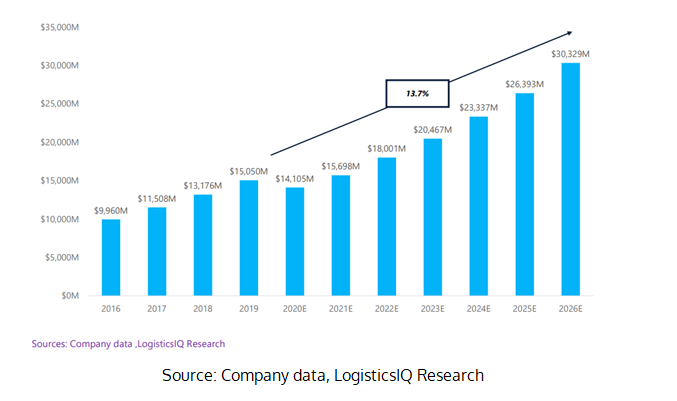

It's no surprise, then, that the market value of warehouse automation technology has been continuously rising since 2020, with a CAGR of 13.7%, and is projected to reach over $30 million by 2026 (see chart below).

Warehouse automation technology that is used to streamline logistic operations

Automated warehouse solutions cover a wide range of technologies designed to reduce manual labor, increase accuracy, and improve the efficiency of material handling. They are a key success factor for e-commerce and have a hugely positive impact on refining warehouse operational efficiency. From autonomous robots and Automated Storage and Retrieval Systems (ASRS) to localization technologies and advanced, highly automated warehouses and supply chain management software, modern warehouse automation is revolutionizing the way e-commerce logistics operate. These technologies are changing the game, enabling faster, safer, and error-free distribution, reducing time to market for products, and ultimately lowering costs for companies and improving productivity of processes. Additionally, these solutions are scalable and can be adapted to fluctuating demand without compromising service quality or operational costs.

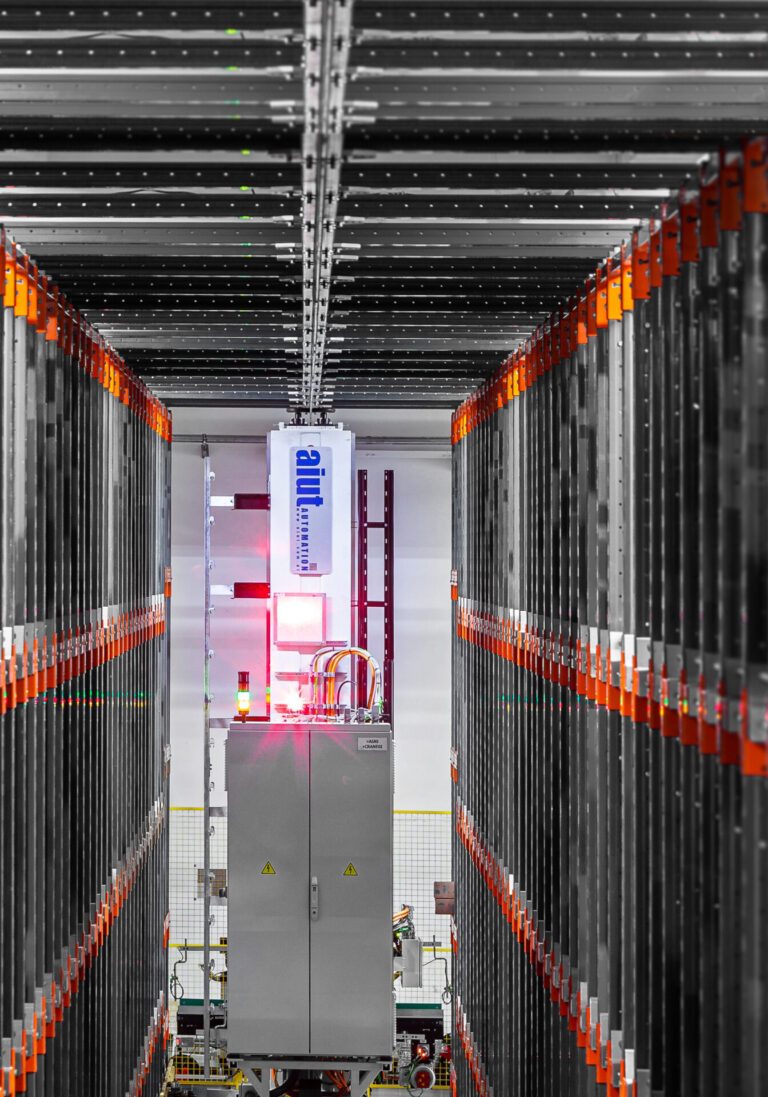

ASRS — warehouse automation solutions

Automated warehouse system technologies: Conveyor Systems

To automate the material handling, automatic transport systems are used. Depending on the needs of a specific facility, various conveyors are designed and implemented. Among the most popular are roller, chain, belt, and modular conveyors. A full analysis of the logistics chain, including the parameters of transported objects, allows for the design of internal transport systems that streamline the flow of goods in warehouses and distribution centers. Learn more about them in the blog article: “Conveyor systems: The key to efficient internal transportation”.

High-bay warehouse

A high-bay warehouse is a specially designed facility, characterized by its great height and the use of automated systems for storing and retrieving goods. Its main advantage is the maximal use of available vertical space, allowing for efficient warehouse space management and increasing the density of goods storage per unit area. Implementing automatic systems in high-bay warehouses includes the use of racks, AGV/AMR, transport systems, and warehouse robots. Automated systems significantly accelerate logistics processes such as storage, picking, or internal transport, while simultaneously reducing the risk of errors, improving work safety, and improving productivity. Read more about it in our blog article: “Logistics reaching clouds – automated high-bay warehouse”.

Implement an automated warehouse model with us!

At AIUT, we design and implement warehouse automation systems based on pallet racking, miniload, automatic Pallet Shuttle systems, and shuttle solutions for container transport for high-performance systems. Our offer also includes specialized solutions, such as shuttle systems for transporting car bodies and large-scale storage. Learn more about the warehouse automation solutions we can design for you.

Smart automated warehouse — Buffer Warehouse

The buffer warehouse, often also called an interim warehouse, plays a key role in supply chain and logistics management. Its main task is the temporary storage of goods to increase flexibility and efficiency in logistics processes. It acts as an intermediary between different stages of production or distribution, allowing for better adjustment to changing market demand, minimizing downtime, and mitigating issues related to differences in production and delivery speeds. Buffer warehouses also enable more effective real-time inventory management, reducing the risk of shortages or excess products, which translates into more efficient and cost-optimized operations. Learn more about them in the blog article “Buffer warehouse — a breakthrough in process optimization!”.

Warehouse Management System: Process Optimization with WMS

The Warehouse Management System (WMS) is a key tool in automating warehouse operations. WMS, or warehouse logistics software, enables precise resource management, optimizing the processes of receiving, storing, picking, and shipping goods. Thanks to the use of advanced IT technologies and automation, the WMS significantly increases the efficiency of warehouse work and minimizes the risk of errors. It also supports decision-making by providing current data on stock levels and trends, contributing to increased overall productivity and reduced operational costs of the warehouse. Learn more about the benefits it can offer here.

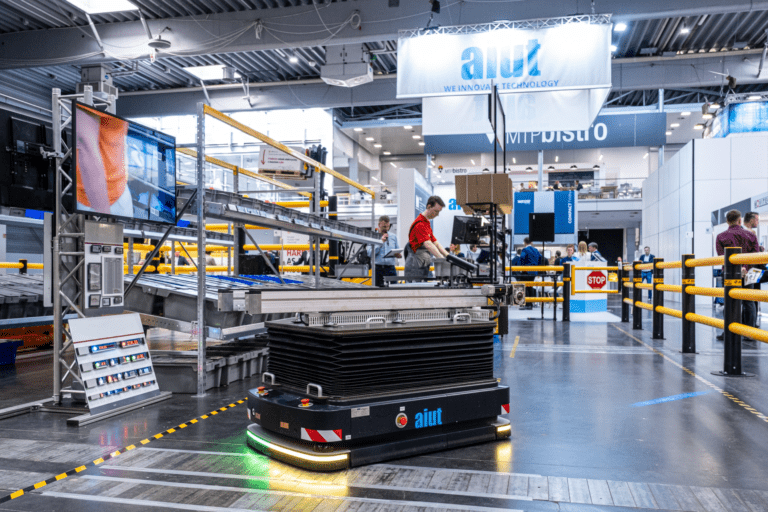

Autonomous mobile robots and automated guided vehicles

Traditional factories often struggle with challenges related to internal logistics, such as increasing the efficiency of material handling, optimizing warehouse space utilization, or minimizing the risk of accidents and equipment damage. Aformic's autonomous mobile robots offer a solution to these problems, thanks to their ability to move independently through factory spaces, perform specific logistics tasks, and communicate with each other and the management system. They are controlled by the intelligent intralogistics platform Qursor, which offers advanced features such as route planning, task optimization, and real-time fleet work monitoring. The platform integrates autonomous mobile robots comprehensively, allowing factories to achieve a higher level of warehouse automation and increase efficiency and flexibility in internal logistics management.

Aformic's solution is adaptive, as the platform can adjust to various production environments and changing work conditions, maintaining high efficiency even in a dynamic industrial environment. Moreover, autonomous robots are equipped with advanced sensors and natural navigation systems, allowing them to avoid obstacles, identify optimal routes, and respond appropriately to changes in their environment.

Benefits of warehouse automation

The direct link between the growth of e-commerce and investments in warehouse automation solutions is evident in the received benefits. Modern warehouses can process orders faster and more accurately, reducing the likelihood of errors and returns. They also offer scalability, allowing companies to adjust operations to current demand. Furthermore, automation reduces the physical burden on workers and increases the safety of working conditions.

E-commerce warehouse automation means:

- Faster order fulfillment: Automation facilitates picking, packing, and shipping, shortening delivery times, and increasing productivity.

- Limited error risk: Warehouse automation systems reduce human error mistakes, e.g., in warehouse picking or inventory management processes,

- Better space utilization: Automation increases warehouse space efficiency, crucial in e-commerce.

- Efficient inventory management: The Warehouse Management System (WMS) provides real-time stock control and inventory accuracy, enabling optimization.

- Easier scalability: Facilitates management of order and inventory growth without additional labor and space resources.

- Safer workplace: Automation reduces the risk of accidents, improving working conditions.

When to start investing in automation?

The decision to start the warehouse automation process requires a thorough understanding of the company's goals and operational capabilities. To introduce automation tools, it's essential to clearly define needs and outline the problems they aim to solve. Although the warehouse is viewed as a whole ecosystem, it's not necessary to implement comprehensive warehouse automation. Focus can be placed on selected warehouse processes and improving their efficiency, adjusting the scope of implementation to the company's capabilities. A good starting point might be implementing a warehouse management system (WMS), followed by moving to more advanced warehouse automation solutions.

Although automation involves high initial costs, integration challenges with existing systems, and the need for continuous maintenance, ultimately, intelligent automation solutions are an investment in the company's long-term success. It's the only way to maintain competitiveness and meet the growing expectations of customers.

Summary

The growth of e-commerce is undoubtedly the main driving force behind warehouse automation, facilitating the fulfillment of the increasing demands of online consumers. As companies strive to increase warehouse efficiency and deliver unmatched services, investing in automation technologies is a step toward a more productive, accurate, and scalable future. Although challenges remain, the potential benefits make the journey towards implementing automation solutions not only necessary but inevitable. The evolution of e-commerce and advanced warehouse technologies is a testament to the power of innovation in meeting the needs of the modern consumer, opening a new chapter in the narrative of logistics and supply chain.

The future of logistics is coming. Automate your warehouse with us!

Don't wait for the competition to outpace you. Consider warehouse automation today. Discover how our innovative automated warehouse solutions can help your company.