Data monitoring in intralogistics – Logistics 4.0

In this article, you will learn:

-

what is intralogistics?

-

what does the intralogistics market look like, and what drives it?

-

why is analyzing data essential, and what are the goals of monitoring data in the industry environment?

-

what are the available data monitoring systems that support data collection and data analytics in internal logistics?

The Fourth Industrial Revolution – Industry 4.0 – has a significant impact on the development of intralogistics, also called internal logistics. Tremendous technological progress, increasingly intelligent devices, and a new approach to intralogistics planning and digital challenges have enabled a significant increase in the efficiency and productivity of in-house operations. It's no wonder that the internal logistics market is growing year by year. According to the Next Move Strategy Consulting company's report, in 2022, its value was estimated at $47.07 billion USD, and forecasts indicate that it will reach $145.49 billion USD by 2030.

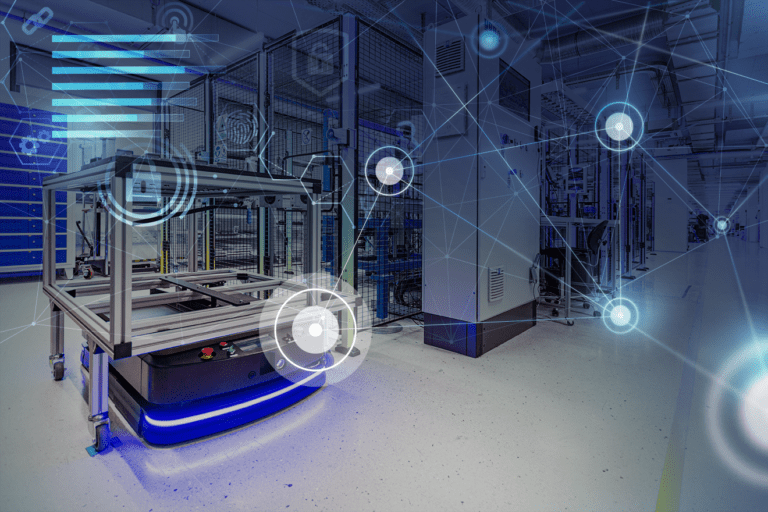

More and more warehouses and distribution centers are adopting new solutions in the field of intralogistics process automation. Current modern intralogistics trends include solutions for transport automation, such as AMR (Autonomous Mobile Robots), transporting robots, conveyor transport systems, more efficient warehousing solutions, such as high-storage systems, and solutions to assist humans in factories, such as collaborative robots. With their help, manufacturing companies can increase production efficiency, improve warehouse process productivity, enhance safety, and streamline flow management, and material transport. However, to successfully implement these solutions in manufacturing facilities, a well-thought-out approach is necessary. So, what steps should be taken before investing in intralogistics process optimization and automation? The answer is simple – understand the objectives of data monitoring in intralogistics and analyze data related to in-house operations – so Industry 4.0.

Intralogistics data driven. The goal of monitoring logistics data in warehouse automation.

Internal logistics, also known as intralogistics, is an integral part of the logistics field. It deals with the organization and management of internal logistical processes within a company. This area of activities focuses on effectively managing the flow of materials and goods, as well as information flow within a facility or warehouse, from the moment they are received until they are issued. Data analysis plays a crucial role here, providing valuable insights into the effectiveness and efficiency of activities at various stages, such as receiving, storing, picking, packing, and shipping of goods. The benefits of collecting, processing, and analyzing data in companies are outlined below.

-

Collect data to identify areas for improvement

Data monitoring ensures continuous and effective performance monitoring of intralogistics processes, enabling the detection of potential issues or delays in the process. It is rare for our plans to align perfectly with reality. We can identify discrepancies by gathering and analyzing reliable data about our processes. Based on this data, we can identify areas that need improvement, implement appropriate preventive measures, and eliminate bottlenecks.

-

Making informed decisions based on relevant data

Making decisions based on reliable data, as opposed to speculation and guesswork, leads us to knowledge-based management. Real-time control of data enables quick decision-making and adaptation to changing conditions. This way, optimized processes will stay with us longer, providing a valuable return on investment.

-

Data processing for continuous improvement of processes and better production management

With current and real-time data, following the Deming cycle, we can identify issues, implement and monitor changes, and implement corrective actions. Automated data monitoring in intralogistics (24/7) and relevant data processes allow for continuous improvement of factory or fulfillment centers' processes following the Kaizen concept. This approach helps companies achieve efficiency and productivity in warehouse processes over the long term.

-

Monitor logistics data for waste elimination, and optimal resource utilization

Through analysis of real-time monitoring logistics data, you can effectively manage resources such as vehicles, equipment, or personnel. Better work organization minimizes the waste of unnecessary movement and ensures optimal resource utilization. Lean production methods help us reduce costs, improve product quality, and better tailor it to customer needs.

-

Understand data monitoring relevance – improve safety in warehouse operations

Real-time data helps improve safety in the warehouse. With them, we can collect information about resource movement, such as monitoring vehicles to verify that they are operating at the appropriate speeds. Additionally, by gathering data on machine operation, we can prevent breakdowns and potential issues. If there are deviations from accepted standards, we can react quickly and oversee occupational health and safety in the factory.

Data sources – tools and technologies for data monitoring and data analytics.

Intralogistics planning is an essential task aimed at synchronizing production and warehouse processes. Therefore, close cooperation between different departments of the company, such as production, logistics, and transportation, is necessary. Furthermore, it is crucial to collect reliable data about intralogistics processes and analyze them appropriately. In this way, we can introduce improvements to intralogistics thoughtfully. Various tools and technologies for data collection methods are available for this purpose. Some of them are presented below.

Real-Time Location Systems. How do they help with monitoring and visualization of warehouse processes? Do they provide high data quality?

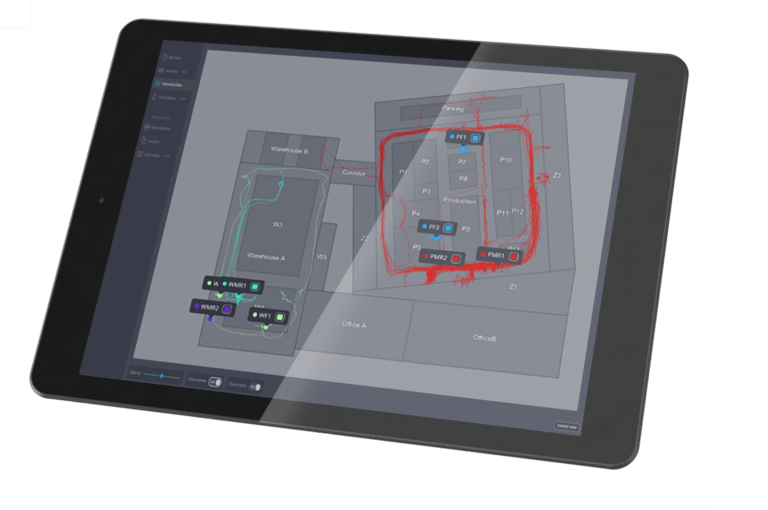

RLTS (Real-Time Location System) is an indoor location system – an industry 4.0 solution – that allows for real-time monitoring of vehicles, individuals, or objects. It is used in factories and warehouses to verify and optimize intralogistics processes. RTLS can operate based on various technologies such as Wi-Fi, RFID (Radio-Frequency Identification), Bluetooth, or UWB (Ultra-Wide Band). UWB is the most accurate among them, providing an accuracy of up to 1 meter. Data collected by the RTLS system can be analyzed using heat maps, from which you can determine the intensity of selected resources over a unit of time. Another method is spaghetti diagrams, which reveal the paths and zones resources have traveled within the warehouse (see the image below). With the help of these tools, we can analyze and optimize delivery routes, verify processes like picking, or monitor fleet performance. Precise location, real-time data, and wireless technology are features of the RTLS system that contribute to increased efficiency of production processes and optimized internal logistics in factories.

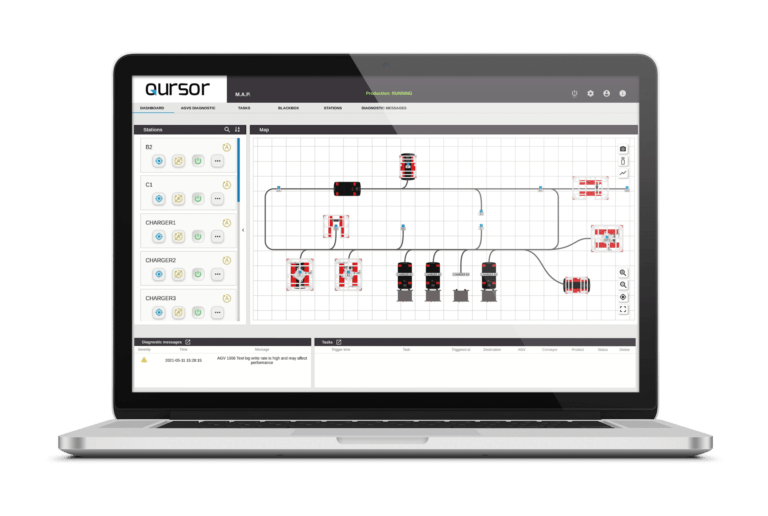

Additionally, RTLS can support other systems, such as Aformic's Qursor, which is used for managing the fleet of Formica autonomous mobile robots (AMRs). This allows us to increase the awareness of autonomous mobile robots about the presence of other resources (locations) in the manufacturing facility. For example, AMR robots would slow down if they detected other resources in their area, or if they knew there were none, they would navigate their designated routes more quickly. Data integration and in-depth analysis would help reduce collision risks in the manufacturing facility, improve operational efficiency, and conduct more precise process simulations. Learn more about Aformic's Qursor solution here.

IoT-driven performance monitoring. Data security for warehouse systems.

The use of interconnected Internet of Things (IoT) devices in a warehouse is essential for collecting and transmitting information from the real environment to the digital realm. IoT sensors are devices of industry 4.0 that gather environmental data and then transmit it over the internet to relevant systems. The data transmitted by these sensors is then analyzed and used for decision-making. For example, the use of IoT sensors allows for continuous monitoring of environmental conditions, such as temperature or humidity. This data is collected and analyzed, enabling the prevention of potential damage or losses, especially for perishable goods or pharmaceutical products. Additionally, with IoT-enabled data process, it is possible to predict potential machinery and equipment failures, allowing for planned maintenance actions and minimizing production downtime.

Warehouse Management Systems (WMS). Streamline warehouse operations.

A Warehouse Management System (WMS) is advanced software that helps companies manage the flow of goods. The WMS system allows for close monitoring and control by collecting data related to all daily warehouse operations. Its tasks include order processing, which involves goods receiving, inventory control, stock management, goods location, and order fulfillment. The WMS solution collects and analyzes data from these stages in real time, enabling more rational decision-making and the smoother flow of a company's intralogistics processes. Learn more about how WMS improves warehouse management efficiency.

Advanced reporting and data analysis systems for intralogistics optimization

Companies use advanced tools for data collection, processing, monitoring and visualization, such as Business Intelligence (BI) platforms and Big Data tools. These tools enable comprehensive data processing and visualization, as well as report generation.

Summary

Understanding the need for intralogistics monitoring and data analysis is crucial to successfully implementing more advanced, automated warehouse solutions. Aligning your perceptions of your processes with reality, based on reliable data monitoring in intralogistics, allows you to achieve greater efficiency and gain a competitive edge in the market. Industry 4.0 encourages us to use modern technologies and tools that enable businesses to monitor logistics data and process it, effectively allowing for a better understanding and optimization of processes in the factory.

Examine internal logistics processes and explore intralogistics monitoring tools with us.

As an integrator of intralogistics, automation, and industrial robotics solutions, we will help you choose data monitoring systems and set a data monitoring strategy. Implement intralogistics and automation solutions with us.