Capabilities

- Plastics processing

- Continuous process automation – chemicals

- Continuous process automation

- Dedicated process automation

- Discrete processes automation

- Production process automation

- Research and control

- Data analysis center

- IoT Ecosystem

- Vision systems

- Software and data integration

- Electricity

- Smart City system integration

- Mechatronics

- Assembly

- Car seats assembly

- Powertrain

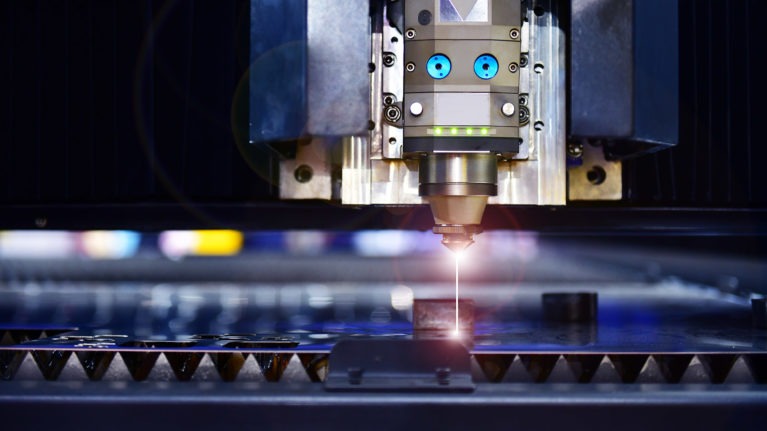

- Laser processing

- Metal processing

- Control and electrical cabinets

- Development projects and documentation

- Robotics

- Industry 4.0

- Material transportation solutions

- IoT Networks

- Detection systems

- Dispensing systems

- IT Systems

- Control systems

- Management systems for fuel terminals

- Station fuel management systems

- Commissioning and tests

- Advanced services

- Welding

- Car assembly

- Packaging systems

- Access control

- Machine park safety audit

The possibility of complex project execution within our own AIUT workshops is one of our advantages. We specialize in the precise processing of plastics using the latest technologies, machines and robotic systems. The skills of our engineering teams allow us to carry out even the most complex orders.

Scroll to see more

Plastics processing in the solutions for industry requires appropriate knowledge, technical experience and high quality equipment. AIUT has all above mentioned so that we are capable of implementing projects for our clients in an all-inclusive manner.

Technical capabilities

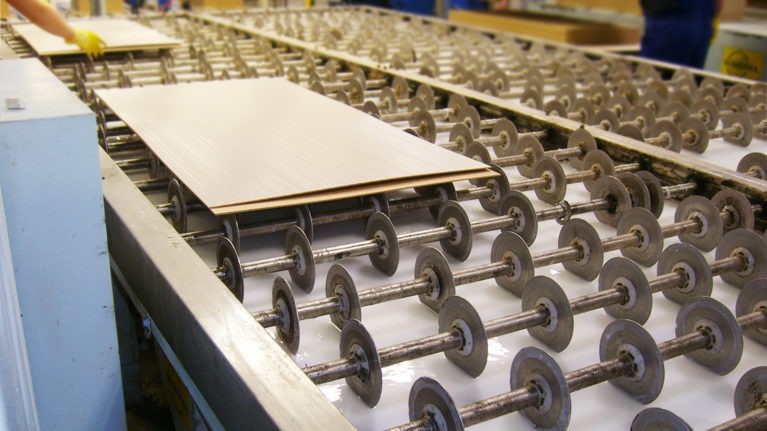

In the production process, AIUT uses the best practices and high-quality equipment for assembly, laser trimming, punching, laminating, and welding of plastics. Our capabilities include:

- insert molding assembly

- linear servo gantry

- adhesives

- automated screwdriving

- degating & punching

- edge wrapping

- laser marking

- laser trimming

- press laminating

- plastics welding

- punching

- robotic mold tending

- trimming

- adhesion promotion / surface energy treatment (plasma/corona)

Industries involved