Capabilities

- Plastics processing

- Continuous process automation – chemicals

- Continuous process automation

- Dedicated process automation

- Discrete processes automation

- Production process automation

- Research and control

- Data analysis center

- IoT Ecosystem

- Vision systems

- Software and data integration

- Electricity

- Smart City system integration

- Mechatronics

- Assembly

- Car seats assembly

- Powertrain

- Laser processing

- Metal processing

- Control and electrical cabinets

- Development projects and documentation

- Robotics

- Industry 4.0

- Material transportation solutions

- IoT Networks

- Detection systems

- Dispensing systems

- IT Systems

- Control systems

- Management systems for fuel terminals

- Station fuel management systems

- Commissioning and tests

- Advanced services

- Welding

- Car assembly

- Packaging systems

- Access control

- Machine park safety audit

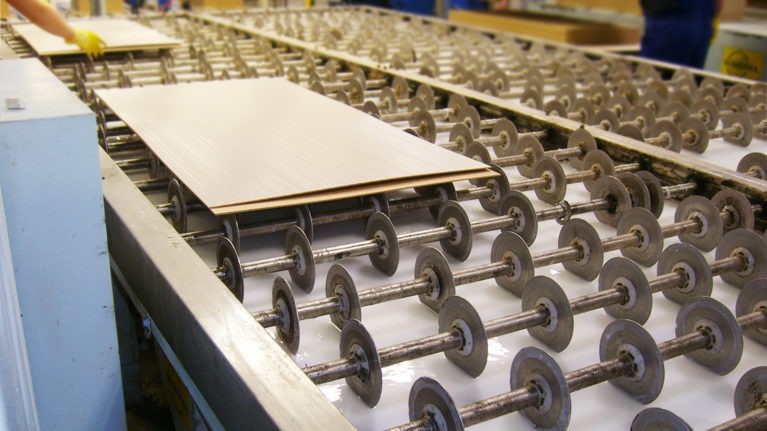

Machining, heat, plastic, chemical handling - our technologies and experience of AIUT teams enables metal element and subassembly modification of any sort.

Scroll to see more

Precise metal processing is one of AIUT specialties. Our teams use the latest technologies of professional machining, bending, grinding and welding, creating elements in accordance with the project.

Technical capabilities

We have many years of experience in cutting, bending, punching, trimming, drilling, and welding. Our capabilities include:

- linear servo gantry

- bending/forming

- crimping

- finishing

- grinding

- laser welding

- machining

- MIG welding

- punching

- resistance welding

- TIG welding

- trimming

- tube bending

- FDS (Flow Drill System)

- electrode/EDM machining

- threading arm

- cutting material on a band saw

- 3, 4 and 5-axis milling

- turning

- hardening

Industries involved