Industries

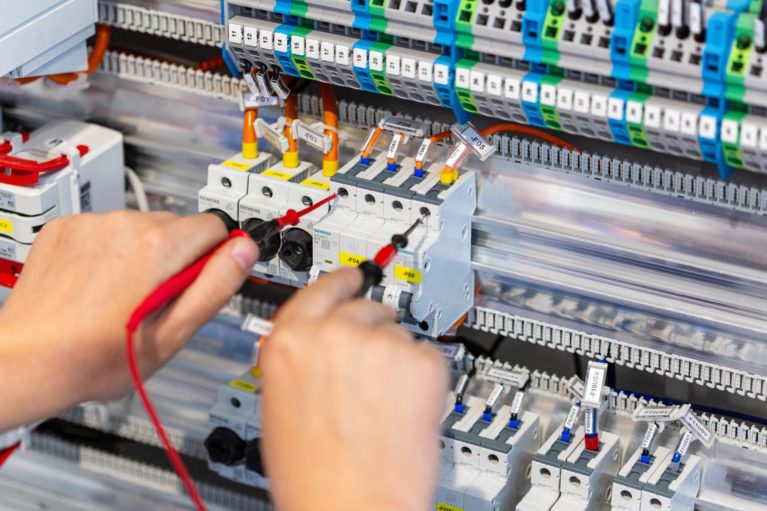

- Electrical industry

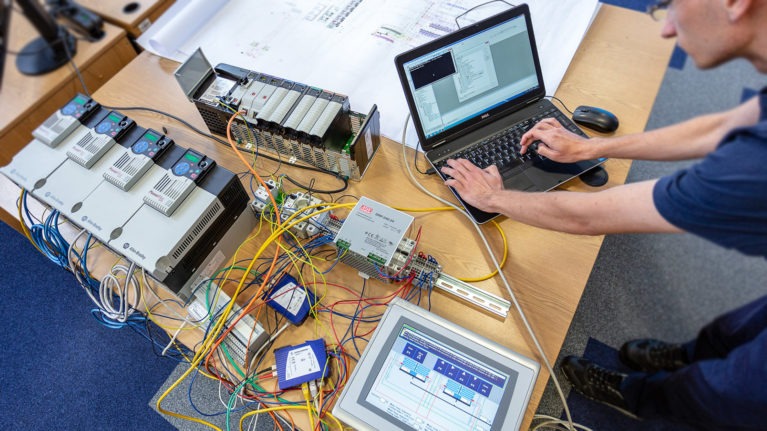

- Business automation

- Energy and municipal services

- Gas, oil and petrochemical industry

- Water and wastewater management

- Mining and mineral industry

- Metallurgy and smelting industry

- Harbours and shipbuilding

- Cement-lime industry

- Chemical industry

- Electronics industry

- Rail industry

- Furniture industry

- Automotive

- Fuel industry

- Paper industry

- Food industry

- Municipalities / Smart City

- Fuel terminals

- Ecology / Recycling

- Rubber and plastic industry

- Lighting industry

- Industrial automation

AIUT works with producers of comprehensive outdoor lighting systems, providing turn-key robotic production lines and automating manufacturing processes in the areas of logistics and warehouse as well as plant management.

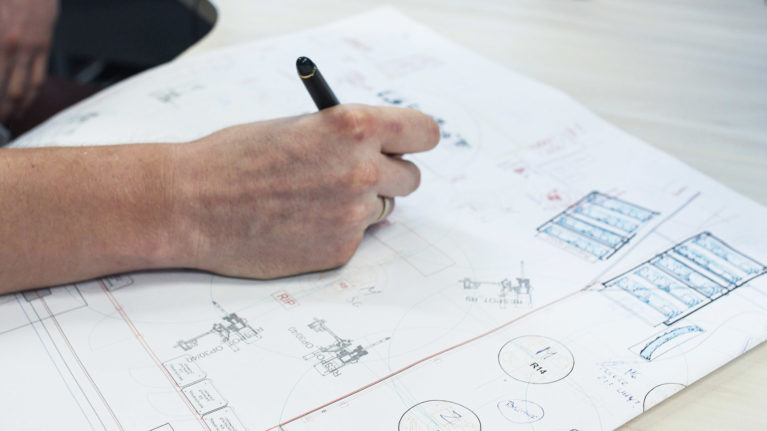

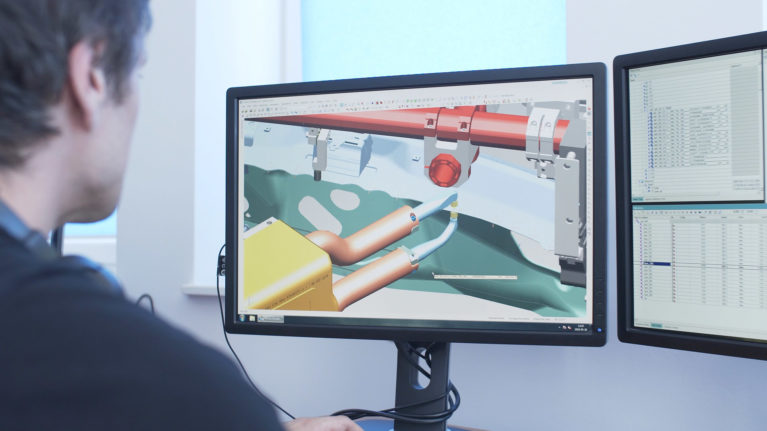

AIUT designs comprehensive solutions for the automation and robotization of production processes. As a response to the individual needs of factories, we provide machines and systems that allow our customers to achieve a leading position in the industry. A production line of aluminum lamp poles for a Polish manufacturer of comprehensive outdoor lighting sets is one of our exemplary implementations.

Case study

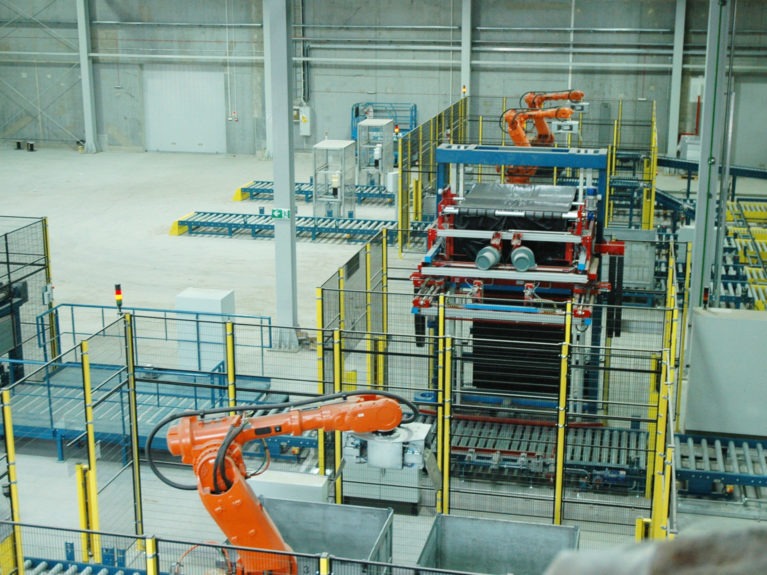

Construction and implementation of a fully robotic production line at the factory of a manufacturer of complex outdoor lighting kits.

The challenge

Full automation of the production process of aluminum lamp poles of different heights in a specific time.

Solution: A new lamp pole every 4 minutes

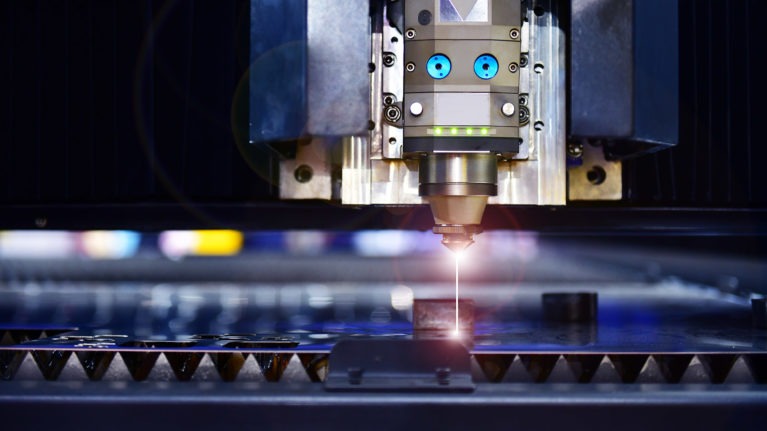

The task consisted of the designing, construction, and implementation of a fully automated robotic process line with laser cutting, grinding, welding, and assembly stations for aluminum poles of different heights. The production line, reaching a total length of 60 meters, has been equipped with 6 industrial robots to ensure the expected quality and efficiency of the process. As a result, a complete lamp pole is made every 4 minutes.

AIUT provided the delivery and integration of all machines and equipment as well as the production process control system utilized within this automated production line.

Business benefits:

- Increased production efficiency

- Comprehensive automation of the production process to ensure a constant, desired count of finished products within a defined strict time

- Guarantee of consistent production quality

- Meeting safety requirements - in terms of both people and process continuity

- Full control over the process with the possibility of event prevention and prediction