- Continuous process automation – chemicals

- Capabilities

Continuous process automation – chemicals

Capabilities

- Plastics processing

- Continuous process automation – chemicals

- Continuous process automation

- Dedicated process automation

- Discrete processes automation

- Production process automation

- Research and control

- Data analysis center

- IoT Ecosystem

- Vision systems

- Software and data integration

- Electricity

- Smart City system integration

- Mechatronics

- Assembly

- Car seats assembly

- Powertrain

- Laser processing

- Metal processing

- Control and electrical cabinets

- Development projects and documentation

- Robotics

- Industry 4.0

- Material transportation solutions

- IoT Networks

- Detection systems

- Dispensing systems

- IT Systems

- Control systems

- Management systems for fuel terminals

- Station fuel management systems

- Commissioning and tests

- Advanced services

- Welding

- Car assembly

- Packaging systems

- Access control

- Machine park safety audit

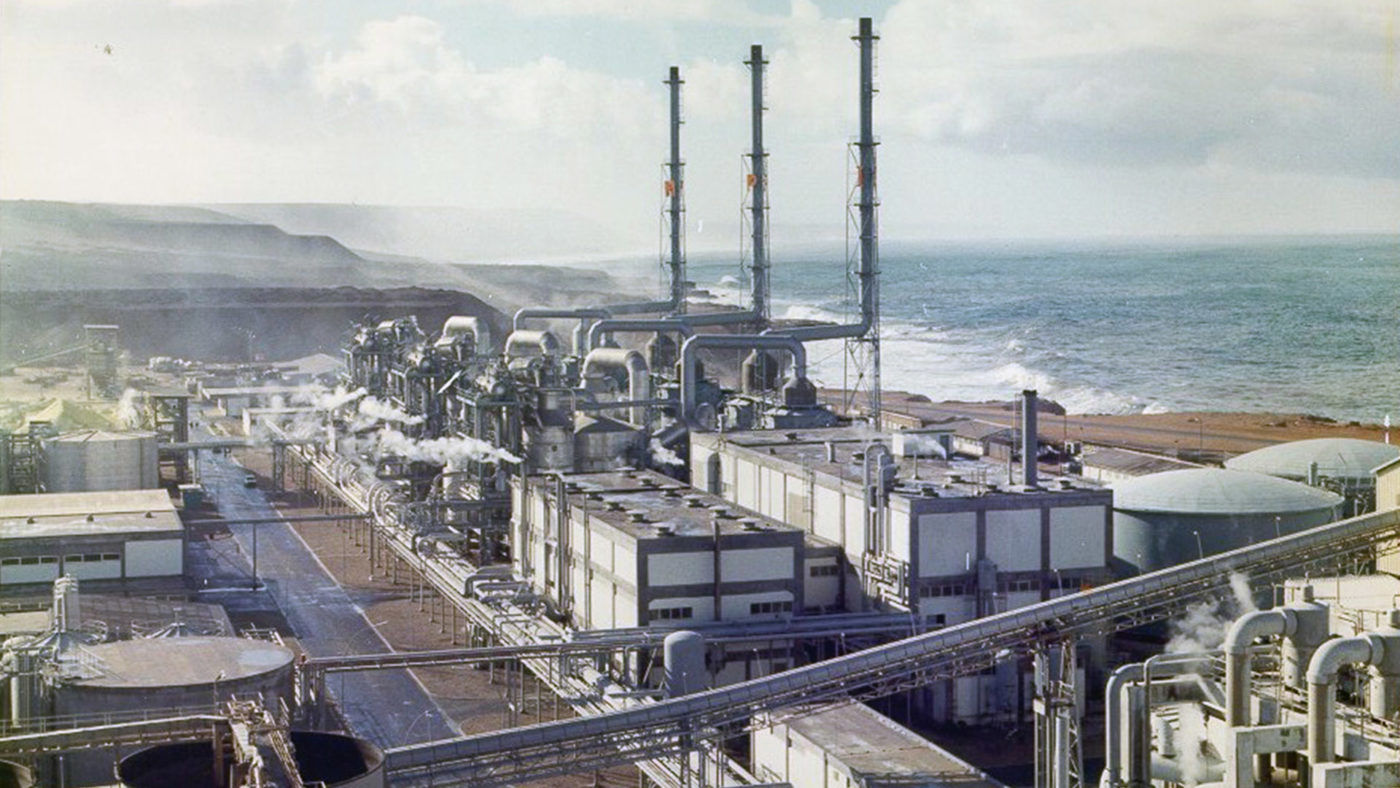

The specialized team of AIUT process engineers responds to the needs of enterprises including chemical, cement and lime, food, petrochemical and energy industries. We automate production and support processes, creating and delivering turn-key advanced installations, including sulfuric acid factories and fuel depots.

AIUT has advanced knowledge regarding, among others, construction of apparatus and entire technological lines in which chemical processes are carried out. Thanks to above mentioned, we can precisely respond to the needs of customers. Our company develops and tests our projects in AIUT research and implementation laboratory in Gliwice.

Technical capabilities

AIUT installations work in the production of e.g. sulfuric acid and sulfur compounds, granulated sulfur, chemical fertilizers and other inorganic compounds. In addition, we design and implement solutions for fuel depots and complete gasoline vapor recovery installations. The engineering team of AIUT Continuous Process Automation Department - Chemicals is responsible for comprehensive service of investment process, including technical and cost analysis, development of technical and detailed design, delivery and assembly of equipment, commissioning of installation together with training of client staff as well as concession and subcontracting documentation. Our capabilities include:

- sulphuric acid production installations

- sulphur transport and storage installations

- fertilizer drying systems

- chemical packaging systems

- installations for unloading vegetable oil from road tankers and rail tank cars

- vegetable oil and esters reloading installations

- liquid fuel and chemical products installations

- complete vapour recovery units for petrol installations

- systems of hermetization and reduction of volatile compounds

- biogas plant control systems

Zastosowanie w branżach