Capabilities

- Plastics processing

- Continuous process automation – chemicals

- Continuous process automation

- Dedicated process automation

- Discrete processes automation

- Production process automation

- Research and control

- Data analysis center

- IoT Ecosystem

- Vision systems

- Software and data integration

- Electricity

- Smart City system integration

- Mechatronics

- Assembly

- Car seats assembly

- Powertrain

- Laser processing

- Metal processing

- Control and electrical cabinets

- Development projects and documentation

- Robotics

- Industry 4.0

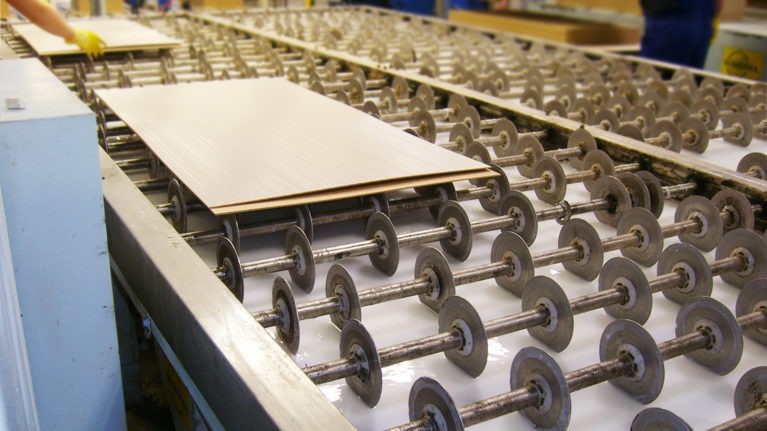

- Material transportation solutions

- IoT Networks

- Detection systems

- Dispensing systems

- IT Systems

- Control systems

- Management systems for fuel terminals

- Station fuel management systems

- Commissioning and tests

- Advanced services

- Welding

- Car assembly

- Packaging systems

- Access control

- Machine park safety audit

We test, control, check operation correctness and functionality of implemented systems, automated production stations and robots. We ensure reliable operation of our solutions.

Scroll to see more

Our knowledge, experience and used technologies allow us to perform detailed analyzes in terms of system operation correctness, conducting advanced tests and functional control and optimization.

Technical capabilities

Among others, we run electrical tests and trials, flow tests and controls, leakage and functional tests as well as vision inspections using ultrafast cameras. Our capabilities include:

- electrical test

- flow testing and control

- strength and distance control

- functional tests

- tightness control

- batch identification

- sound

- video inspection using ultrafast cameras

- 2D and 3D laser scanners

- lvdt - using precision mechanical sensors

- p & i installation design - mechanical and electrical part, including legal measuring lines, flow computers and tank measurement system

- fire and gas detection system & fire protection system design

- control system hardware and software engineering

- quality assurance system

Industries involved